On the Right Track: How Digital Transformation and ERP are Powering the Future of the Rail Industry

2025-10-01 · By Anil Kancharla · 7 min read

❤️ 0 Likes · 👁️ 0 Views

AI-generated image for illustration purposes only.

AI-generated image for illustration purposes only.

On the Right Track: How Digital Transformation and ERP are Powering the Future of the Rail Industry

AI-generated image for illustration purposes only.

AI-generated image for illustration purposes only.

On the Right Track: How Digital Transformation and ERP are Powering the Future of the Rail Industry

For more than a century, the rail transportation industry has been the steel backbone of global commerce and a vital artery for public mobility. It’s an industry of immense scale and complexity, responsible for moving vast quantities of freight and millions of passengers with precision and reliability. But as we navigate the mid-2020s, the rail sector is at a pivotal junction, facing a new set of demanding tracks.

Today’s rail operators are contending with an urgent mandate for sustainability, intense pressure to integrate seamlessly into a volatile global supply chain, the monumental task of maintaining thousands of miles of aging infrastructure, and a new generation of passengers and freight customers demanding greater visibility and a digital-first experience. The traditional, siloed operational models of the past are no longer sufficient to keep the industry moving forward.

The path to a more efficient, resilient, and profitable future is being laid by digital transformation. And the central nervous system connecting every locomotive, every piece of track, every shipment, and every passenger is a modern, powerful Enterprise Resource Planning (ERP) system.

This in-depth blog post will explore the complex world of the modern rail industry, uncover the immense opportunities of its digital evolution, and provide a comparative analysis of leading ERP solutions designed to help rail operators get on the right track for the future.

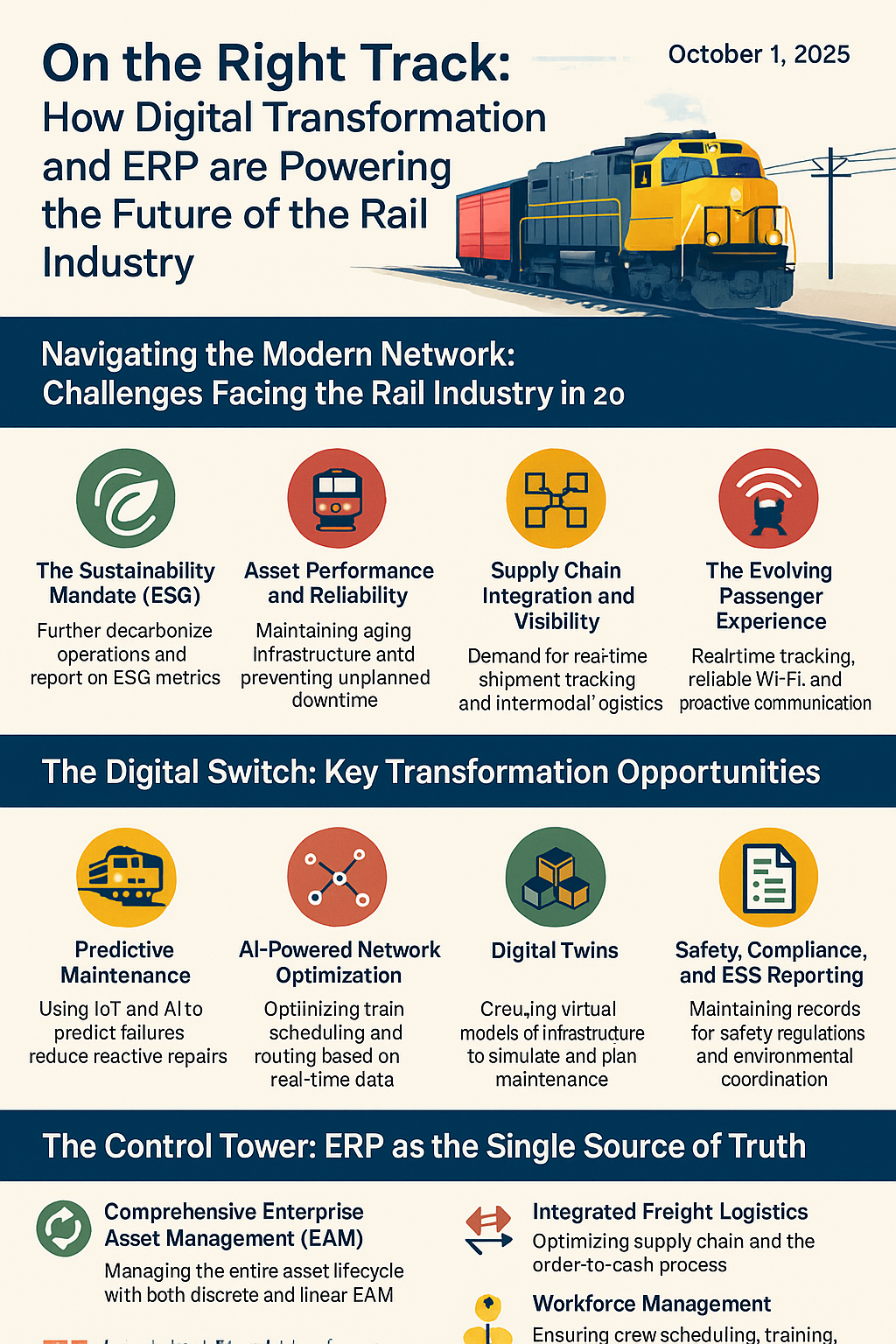

Navigating the Modern Network: Challenges Facing the Rail Industry in 2025

The rail industry, encompassing freight, passenger, and intermodal transport, is facing structural shifts that demand a smarter approach to operations.

- The Sustainability Mandate (ESG): Rail is already one of the most sustainable modes of transport, but the pressure to do more is immense. Operators are facing strong demand from investors, regulators, and customers to further decarbonize operations, reduce emissions, improve energy efficiency, and report transparently on Environmental, Social, and Governance (ESG) metrics.

- Asset Performance and Reliability: A rail network is a colossal, capital-intensive system of assets, from locomotives and railcars (rolling stock) to thousands of miles of tracks, bridges, and signals (linear assets). Ensuring the reliability and safety of this aging infrastructure, preventing unplanned downtime, and optimizing maintenance budgets are monumental challenges.

- Supply Chain Integration and Visibility: In today's interconnected world, rail is a critical link in the global supply chain. Freight customers no longer just want their cargo moved from Point A to Point B; they demand real-time visibility, accurate ETAs, and seamless integration with other transport modes like trucking and shipping (intermodal logistics).

- The Evolving Passenger Experience: Passenger rail operators face growing competition and heightened customer expectations. Modern travelers expect a frictionless journey, from easy online booking and real-time train tracking on a mobile app to reliable onboard Wi-Fi and proactive communication during service disruptions.

- Safety and Regulatory Compliance: Safety is the bedrock of the rail industry. Operators must adhere to a complex and ever-evolving web of stringent safety regulations, such as Positive Train Control (PTC) mandates, and maintain meticulous records for compliance and incident prevention.

The Digital Switch: Key Transformation Opportunities

Digital transformation, often dubbed "Rail 4.0," provides a powerful set of tools to address these challenges, unlocking new levels of efficiency, safety, and service quality.

-

The Intelligent Asset: Predictive Maintenance for Rolling Stock and Infrastructure This is the most significant leap forward in rail operations. By equipping locomotives, railcars, and tracks with thousands of IoT sensors, operators can collect a constant stream of real-time data on everything from wheel bearing temperature and engine vibration to track integrity. AI and machine learning algorithms then analyze this data to predict potential failures before they happen, allowing maintenance to be scheduled proactively. This shifts the entire paradigm from costly, reactive repairs to data-driven, predictive asset management.

-

AI-Powered Network Optimization and Planning Artificial intelligence is becoming the new signalman for the entire network. AI can analyze vast datasets—including traffic patterns, weather, crew availability, and customer demand—to:

- Optimize train scheduling and routing to improve network fluidity and reduce congestion.

- Improve demand forecasting for both freight and passenger services.

- Automate yard management and the complex "consist" building of freight trains.

-

Digital Twins for Infrastructure Management A digital twin is a living, virtual 3D model of a physical asset, like a railway bridge, a complex switch, or an entire section of track. By feeding it real-time data from sensors, drones, and inspection reports, engineers can simulate the effects of stress and weather, plan maintenance interventions with surgical precision, and optimize infrastructure upgrades without disrupting service.

-

Enhanced Supply Chain Visibility and Intermodal Logistics For freight rail, digital platforms are breaking down communication silos. Real-time GPS and sensor data from railcars, combined with integrated logistics platforms, provide shippers with the end-to-end visibility they demand. This allows for better coordination at intermodal terminals where containers are transferred between trains, trucks, and ships, creating a more fluid and reliable supply chain.

The Control Tower: ERP as the Single Source of Truth

With a torrent of data flowing from rolling stock sensors, trackside monitors, scheduling systems, and customer apps, how does a rail operator unify this complexity to run a safe and profitable business? This is the mission-critical role of an Enterprise Resource Planning (ERP) system designed for asset-intensive industries like transportation.

The ERP is the operational, financial, and asset management backbone. It integrates every function—from maintenance and engineering to logistics, finance, and human resources—into a single, unified platform.

Core Benefits of a Rail-Focused ERP:

- Comprehensive Enterprise Asset Management (EAM): This is the heart of a rail ERP. It manages the entire lifecycle of every asset, from locomotives to the last mile of track. It schedules complex maintenance programs, tracks part and component history for regulatory compliance, manages warranties, and integrates data from predictive maintenance systems to generate work orders automatically. It is specifically designed to handle both discrete assets (rolling stock) and linear assets (track).

- Integrated Supply Chain and Logistics for Freight: The ERP manages the entire freight order-to-cash process. It handles customer contracts, complex rating and billing, tracks shipments, and provides the data needed for seamless intermodal operations.

- Workforce Management for a Complex Crew: The system helps manage the complex scheduling, training, and certification requirements for train crews, engineers, and maintenance staff, ensuring that all personnel are qualified and compliant with labor rules and safety regulations.

- Robust Financials for Capital-Intensive Operations: A rail ERP is built to handle the industry's unique financial needs, including managing multi-billion dollar capital improvement projects, complex asset accounting and depreciation, and detailed profitability analysis by route or line of business.

- Safety, Compliance, and ESG Reporting: The ERP serves as the system of record for safety and compliance. It tracks incidents, manages inspections, and provides a clear audit trail for regulators. Crucially, it also centralizes the operational data (e.g., fuel consumption, emissions) needed for transparent and accurate ESG reporting.

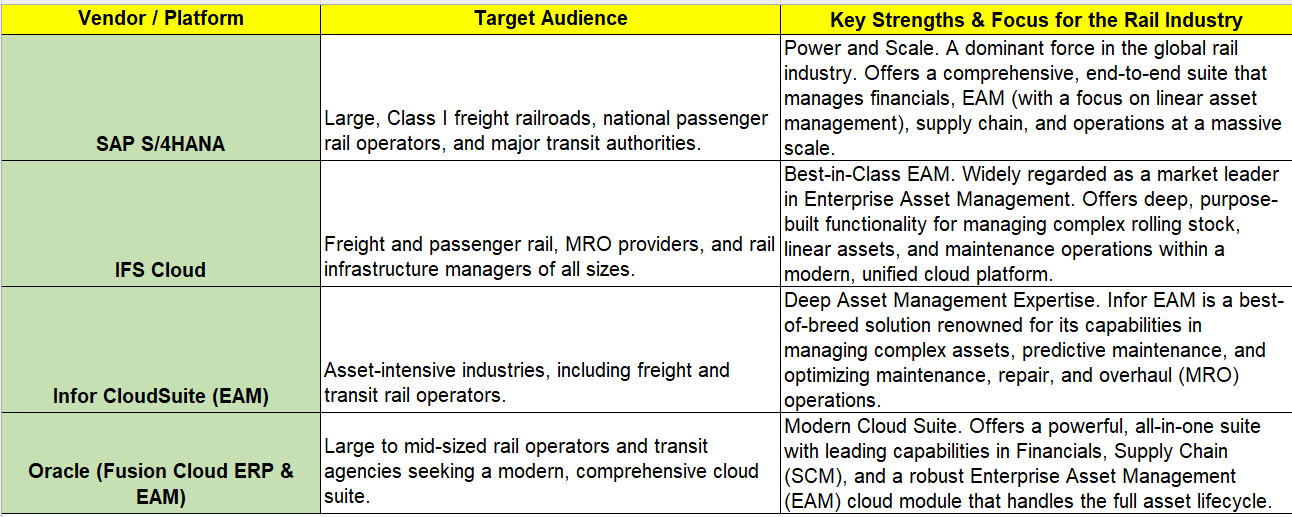

Choosing Your Engine: A Look at Leading ERPs for the Rail Industry in 2025

The ERP market for this asset-intensive sector includes global giants and deep industry specialists who understand the critical demands of rail operations.

On Track for a Smarter Future

The future of rail transportation is not just about more powerful locomotives or faster trains; it's about a smarter, more connected, and more sustainable network. The operators who will lead this new era will be those that harness data to create hyper-efficient, reliable, and safe operations that meet the evolving demands of both freight and passenger customers.

Building this future is impossible with fragmented, legacy systems. It requires a powerful, integrated digital core. By investing in a modern, industry-specific ERP system, rail operators can break down operational silos, unlock the full potential of their data, and build an enterprise that is firmly on the right track for a more profitable and sustainable future.

💌 Enjoyed this article?

If you found this post valuable, subscribe to my newsletter for more insights on digital transformation, AI, and business innovation.

👉 Subscribe to the newsletterOr let’s connect on LinkedIn — I share weekly content that’s practical for CIOs, CFOs, and transformation leaders.

🔗 Connect with me on LinkedIn