What is Digital Supply Chain

2025-05-05 · By Anil Kancharla · 8 min read

❤️ 0 Likes · 👁️ 0 Views

What Is a Digital Supply Chain?

Understanding the Technology-Driven Future of Supply Networks

Understanding the Technology-Driven Future of Supply Networks

As innovations emerge every day and technological advancements become commonplace, it is essential to understand how these changes impact our daily lives. A few decades ago, businesses did not emphasize the importance of supply chains, but today, understanding supply chains is crucial for business success.

The digital supply chain goes beyond merely adopting the latest technologies; its ultimate goal is to increase value through a holistic approach. A digital supply chain can be a platform to improve supply chain operations by enabling technologies to meet customer needs.

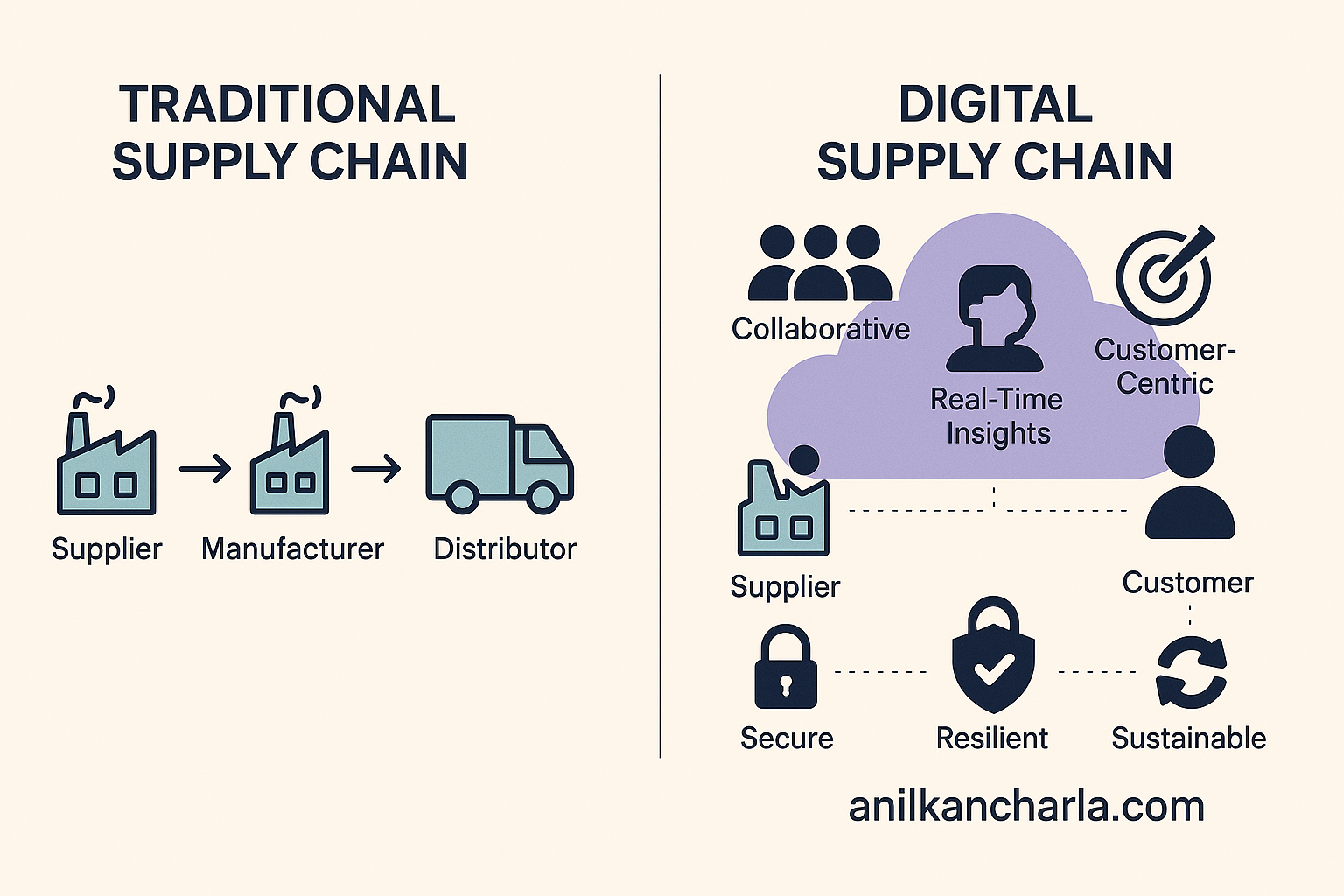

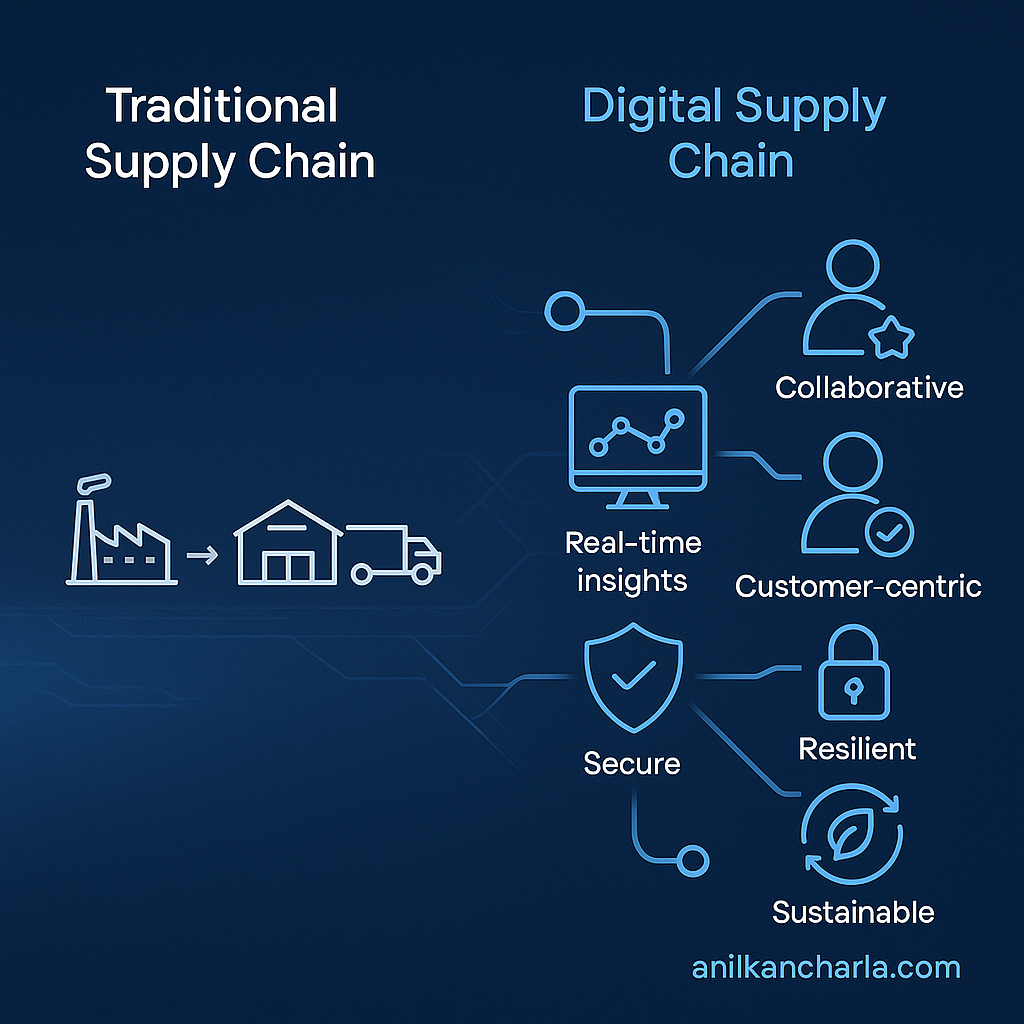

🔍 Key Features of a Digital Supply Chain

A comprehensive digital supply chain should have the following features:

✅ Collaborative

✅ Real-Time Insights

✅ Customer-Centric

✅ Secure

✅ Resilient

✅ Sustainable

Collaborative

When multiple entities are working toward a common goal, meeting customer's needs, collaboration is essential to avoid operating in silos. Proper handshake between parties is particularly crucial for the supply chain, as there is a flow of information, finances, and physical goods among various parties. A lack of collaboration can pose significant risks to the supply chain.

📦 For example, when you order through an e-commerce portal, most e-commerce companies do not maintain stock; instead, they either source products from suppliers or operate on a make-to-order basis. This process requires collaboration between suppliers, manufacturers, retailers, and wholesalers to ensure that the product reaches you. Therefore, a digital supply chain must support practical cooperation between all parties.

Real-Time Insights

Every movement, whether awake or asleep, generates a continuous flow of data that needs to be stored, processed, and interpreted to gain meaningful insights. If something abnormal occurs, the business must take corrective actions to prevent potential failures. Digital supply chains must provide real-time reporting to enable companies to make informed decisions.

🚚 For instance, if I order a lawn mower shipped from Ohio to Texas, it may be transported by road in a cargo vehicle. I can track the latest status of the order placed. If there is a delay due to an unexpected event, I will receive a message about the delay and an update on the latest status.

Customer-Centric

Business models have evolved to center the customer in all business systems. Therefore, digital supply chains should be evaluated not by the level of automation implemented but by the value customers will receive from the transformation.

Secure

The supply chain has three main flows: information, financial transactions, and physical goods. A digital supply chain must ensure that all these flows are delivered promptly, agile, and securely. Cybersecurity has become a priority for everyone in this digital age, as we need to ensure that data is secure and safe.

🔐 Information must flow seamlessly in digital supply chains, with communication taking place over secure, protocol-based networks. Financial transactions involve sensitive information, and payment methods must be conducted securely and continuously. Additionally, the physical movement of goods ensures that digital supply chains are protected by utilizing IoT and AI-based video monitoring to prevent potential theft.

Resilient

Macro environment factors are outside the organization's control, disrupting supply chain flow. Another essential feature of a Digital supply chain is resilience. Changes can be anything from entering new markets to moving the warehouse location or manufacturing facility to mergers and acquisitions. Digital Supply Chains must be ready to adjust to change and quickly function effectively. Macro environment factors are beyond an organization's control and can disrupt supply chain flows. An essential aspect of a digital supply chain is its resilience. Changes may include entering new markets, relocating warehouses or manufacturing facilities, or undergoing mergers and acquisitions. Digital supply chains must be prepared to adapt to these changes and function effectively and quickly.

Sustainable

Businesses must be socially responsible toward the community and work toward common goals for humanity. Products developed should be designed with climate and environmental friendliness to ensure we leave a better world for future generations. Digital supply chains should support initiatives like ESG (Environmental, Social, and Governance), recycling, and the reuse of materials for producing goods and services to promote sustainable business practices.

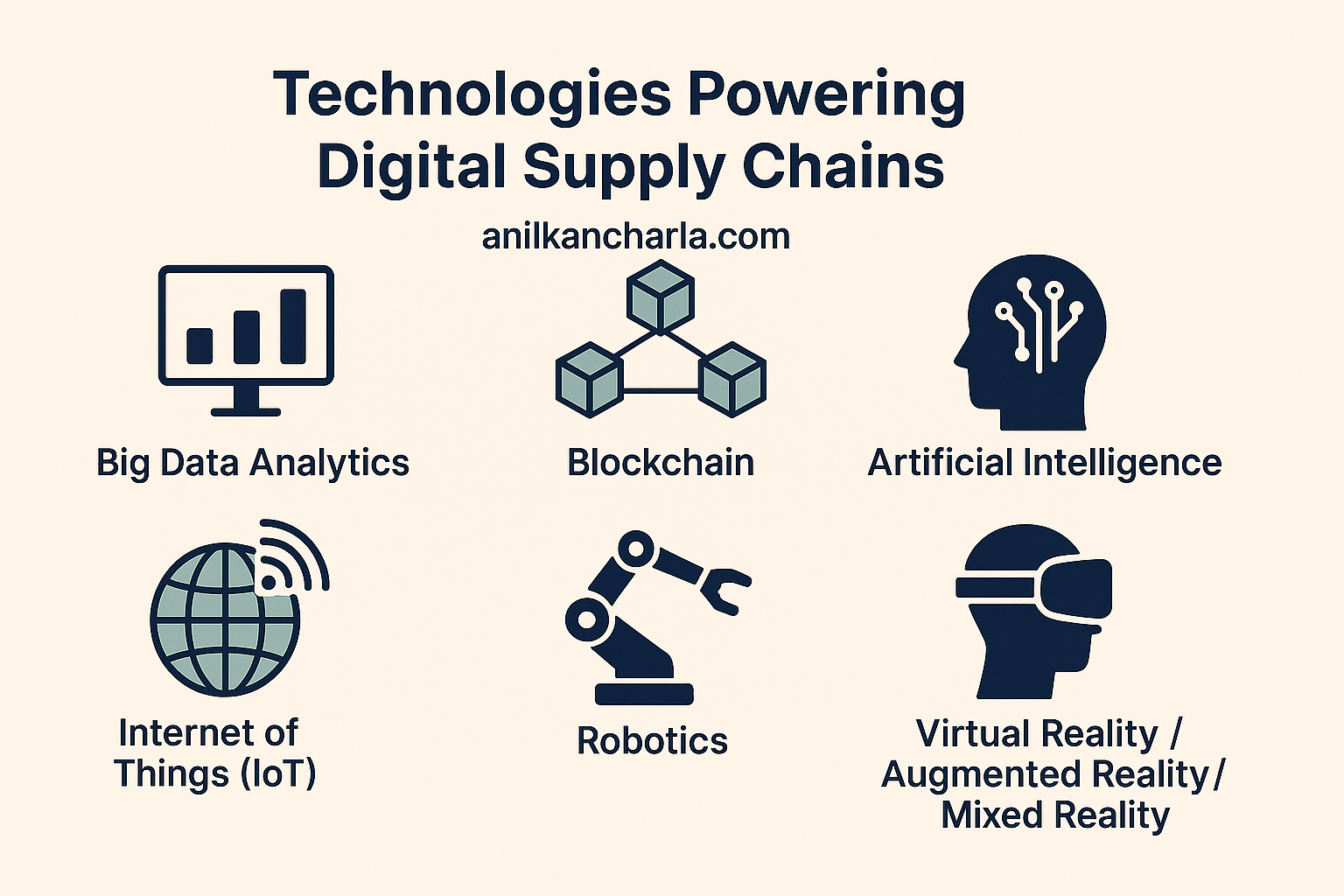

⚙️ Technologies Powering Digital Supply Chains

📊 Big Data Analytics

🔗 Blockchain

🌐 Internet of Things (IoT)

🤖 Artificial Intelligence

🦾 Robotics

🕶️ Virtual Reality / Augmented Reality / Mixed Reality

Big Data Analytics

In this information age, data is considered the new gold. Vast amounts of data are generated every minute across the globe, existing in both structured (such as databases) and unstructured formats (like text files, images, and binary large objects). Big data is the concept that employs various tools and frameworks to store and process this data, ultimately providing meaningful insights.

Use Case:

Develop a supply chain control tower that offers real-time insights through a dashboard featuring different metrics. This will facilitate the analysis of various data sets, enabling informed decision-making and more effective conclusions.

Blockchain

Blockchain has evolved from the concept of a public ledger, in which a group approves of participants. Typically, ledgers are maintained individually by different entities. Each entity updates its ledger separately when a transaction occurs, leading to discrepancies and potential delays in processing transactions. However, with blockchain, multiple parties are involved; if all parties agree and approve a transaction, it is validated.

Use Case:

Consider a scenario where goods are sold to an international customer. A smart contract can be established with distributed ledger technology to automate payment. Both parties agree upon Terms, and the contract is created. For instance, once the goods are shipped and the export documentation is updated at the port, 25% of the payment is released. After the goods clear customs with the importing authorities, an additional 50% is released. Finally, after inspection and confirmation of the goods, the remaining 100% is released. All these transactions are recorded in the public or private ledger as long as they are completed and confirmed by all parties involved.

Internet of Things (IoT)

The Internet of Things (IoT) is how companies are tracking their devices after the sale. It also helps them with preventive or predictive service maintenance of an asset. Not only is IoT beneficial for asset maintenance, but it also aids in tracking materials as they move from one location to another. It provides constant signals for accurate tracking, enabling businesses to plan effectively.

Use Case:

A container of furniture shipped from a Vietnamese port is on its way to the U.S. for one of the large retailers expecting this shipment to plan for the upcoming promotional season. The retailer can plan their imports and logistics with accurate tracking information, ensuring their warehouse has enough stock for the business. This tracking is accomplished through IoT devices connected to the container, which share real-time data for monitoring.

Artificial Intelligence

Digital supply chains not only report data based on frequent patterns identified through machine learning techniques but can also learn and become intelligent. Instead of having someone make decisions for the system to act upon, the system can be smart enough to predict outcomes and make decisions independently, thereby avoiding repetitive tasks.

Use Case:

Consider a scenario where a supplier sends a manual invoice in PDF format. Someone must manually extract the document's data to create payable invoices. However, with document recognition technology, AI can read the document and automatically generate the invoices.

Robotics

Human-less factories are no longer a concept; they have become a reality. Many factory workers have been downsized and replaced by advanced industrial robots. These intelligent machines significantly reduce the chances of errors and improve quality. The integration of advanced robotics will benefit digital supply chains.

Use Case:

For example, in the mid-1990s, car manufacturing processes were primarily operated by human workers. Today, each step of the process has been replaced by industrial robots, and in some factories, the entire operation is fully automated.

VR/AR/MR

When I first encountered the concepts of VR, AR, and MR, I struggled to understand how this technology could fit into the supply chain process. However, after using it as an end user during online purchases, I realized I was relying on it more often. With remote work becoming increasingly common, virtual reality makes virtual connections more effective than traditional online meetings. Beyond this, it also offers significant benefits for simulating real events for workforce training. This technology is a valuable addition to the digital supply chain toolkit.

Use Case:

A construction company can present its design ideas in a 3D view instead of a 2D format, allowing the audience to grasp the designer's vision better and visualize the concept more effectively.

🎯 Final Thoughts

The digital supply chain is not limited to specific technologies. As we continue to innovate, new technologies constantly disrupt existing frameworks, and their life cycles shrink every day. While more technologies can be added or replaced, one thing remains constant: the value provided to customers at the end of each supply chain, whether traditional or digital. We must always keep in mind the primary objective of a supply chain, which is to meet customer expectations.

🧭 Meet customer expectations efficiently, sustainably, and intelligently.

Digital supply chains are no longer optional—they’re a competitive necessity.

💌 Enjoyed this article?

If you found this post valuable, subscribe to my newsletter for more insights on digital transformation, AI, and business innovation.

👉 Subscribe to the newsletterOr let’s connect on LinkedIn — I share weekly content that’s practical for CIOs, CFOs, and transformation leaders.

🔗 Connect with me on LinkedIn