From Crude to Customer: Mastering the Downstream Oil and Gas Process with Digital Transformation and ERP

2025-06-25 · By Anil Kancharla · 7 min read

❤️ 0 Likes · 👁️ 0 Views

From Crude to Customer: Mastering the Downstream Oil and Gas Process with Digital Transformation and ERP

The journey of oil and gas from the reservoir to the end-user is a complex, multi-stage marathon. The final, critical leg of this race is the downstream sector, the point where raw hydrocarbons are transformed into the fuels and products that power our daily lives. From massive refineries to the local gas station, this sector is a high-stakes environment of thin margins, intense competition, and mounting pressure for greater efficiency, safety, and sustainability.

In this volatile landscape, digital transformation is no longer a futuristic buzzword; it's the most critical lever for survival and success. At the core of this transformation is the indispensable role of Enterprise Resource Planning (ERP) software. A modern ERP system acts as the digital backbone, integrating complex processes, providing real-time visibility, and empowering downstream players to navigate challenges and seize opportunities.

This in-depth blog post will explore the intricate world of the downstream oil and gas process, uncover the immense opportunities for digital evolution, and provide a comparative analysis of leading ERP solutions that are redefining what's possible in this vital sector.

The Final Transformation: Understanding the Downstream Value Chain

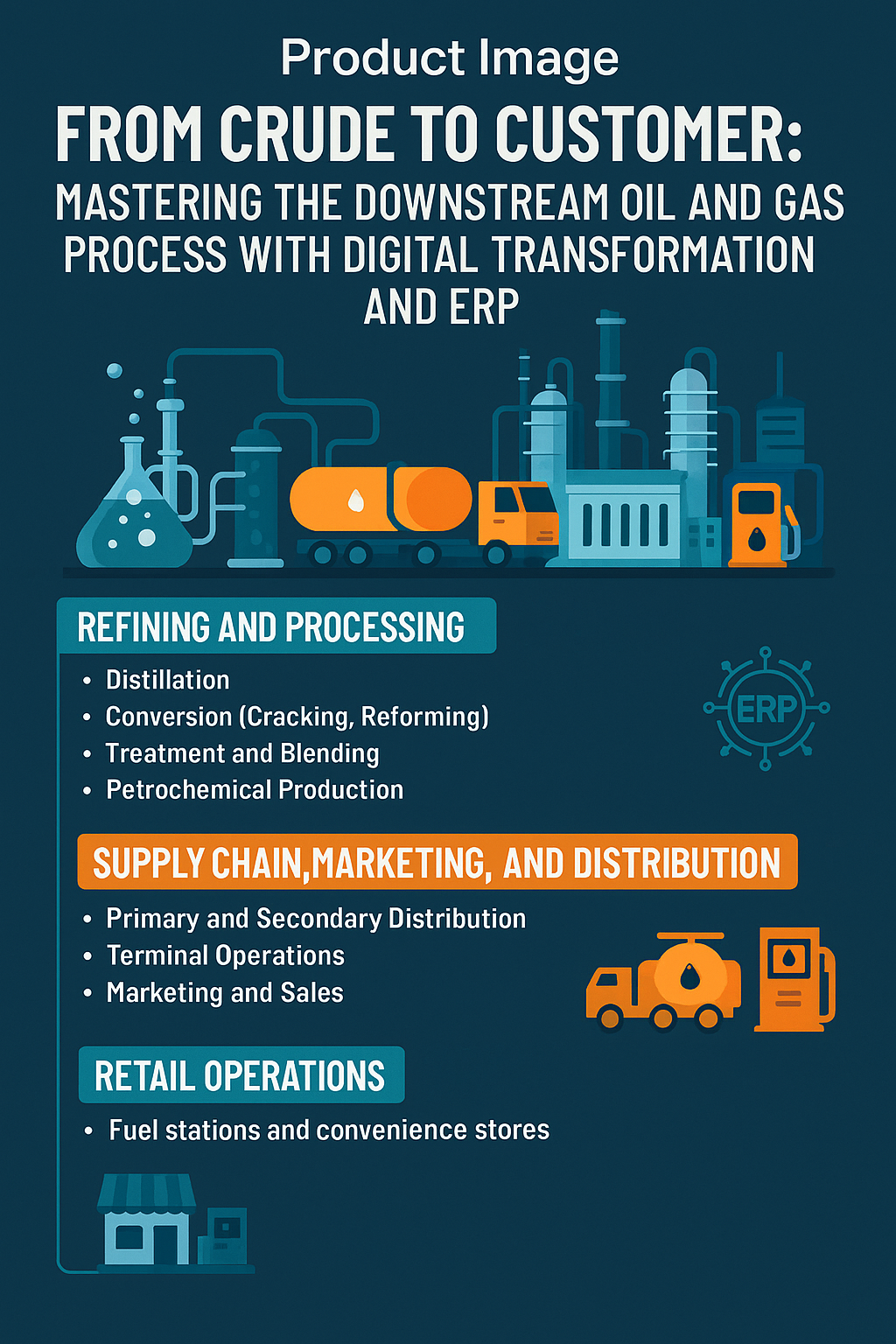

The downstream sector is where the true value of crude oil and natural gas is unlocked. It's a complex interplay of large-scale industrial processes and sophisticated commercial operations, primarily encompassing three main areas:

1. Refining and Processing: This is the industrial heart of the downstream sector. Giant refineries and petrochemical plants take crude oil and natural gas liquids (NGLs) and, through a series of complex chemical and physical processes, convert them into a vast array of finished products.

- Distillation: The initial step where crude oil is heated and separated into various components or "fractions" based on their boiling points, such as gasoline, kerosene, and diesel.

- Conversion (Cracking, Reforming): Sophisticated processes that break down heavier hydrocarbon molecules into lighter, more valuable ones (like gasoline) to meet market demand.

- Treatment and Blending: Removing impurities (like sulfur) and blending different components to create finished products that meet precise quality specifications and regulatory standards.

- Petrochemical Production: A specialized segment where fractions are used as feedstock to produce chemicals that form the building blocks for plastics, fertilizers, synthetic rubbers, and countless other everyday materials.

2. Supply Chain, Marketing, and Distribution: Once products are refined, they must be efficiently and safely transported to the market. This involves a complex logistics network.

- Primary Distribution: Moving large volumes of products from refineries to major storage terminals via pipelines, tankers, and rail.

- Terminal Operations: Managing large storage facilities where products are held, blended, and loaded onto trucks for secondary distribution.

- Secondary Distribution: The "last mile" delivery of fuels via tanker trucks to retail stations, commercial customers, and industrial sites.

- Marketing and Sales: Developing strategies to sell refined products in wholesale, commercial, and retail markets, including managing branding, pricing, and customer relationships.

3. Retail Operations: This is the most public-facing part of the downstream sector, primarily consisting of the vast network of retail fuel stations. It involves managing fuel inventory, point-of-sale (POS) systems, convenience store operations, customer loyalty programs, and payment processing.

The Digital Imperative: Why Transformation is Non-Negotiable for Downstream

The downstream sector is navigating a perfect storm of challenges: volatile crude oil prices, razor-thin refining margins, stringent environmental regulations, shifting consumer demand (driven by the rise of electric vehicles), and the constant need to ensure operational safety. Digital transformation offers a powerful toolkit to not only weather this storm but to thrive within it.

Key Digital Transformation Opportunities:

- The Smart Refinery: Integrating Internet of Things (IoT) sensors, AI, and machine learning to create a "digital twin" of the refinery. This allows for real-time monitoring of all equipment, predictive maintenance to prevent costly unplanned shutdowns, and process optimization to maximize yield and energy efficiency.

- Integrated Supply Chain Visibility: Connecting every point in the supply chain—from the refinery gate to the terminal, the delivery truck, and the retail station—on a single platform. This enables real-time inventory management, optimized logistics, and a dramatic reduction in transportation costs.

- Advanced Analytics and AI-Powered Pricing: Leveraging big data and AI to analyze market trends, competitor behavior, and local demand patterns to optimize fuel pricing in real-time, maximizing margins at both wholesale and retail levels.

- Commodity Trading and Risk Management (CTRM): Using sophisticated software to manage the immense financial risks associated with buying crude oil and selling refined products in volatile global markets.

- Enhanced Safety and Compliance: Employing digital tools to monitor emissions, manage safety procedures, track employee certifications, and automate regulatory reporting, ensuring a safer work environment and seamless compliance.

The Digital Backbone: The Role of ERP in Downstream Operations

To harness these digital opportunities, downstream companies need a central, intelligent platform that can unify data and processes from every corner of the business. This is the role of a modern, industry-specific Enterprise Resource Planning (ERP) system.

An ERP designed for the downstream sector moves beyond basic accounting to provide a comprehensive suite of tools that manage the entire value chain, from crude procurement to the customer transaction.

Critical ERP Capabilities for Downstream:

- Hydrocarbon Supply Chain Management: Managing the complex logistics of primary and secondary distribution, including terminal management, scheduling, and real-time tracking of product movements.

- Refining and Processing Integration: Linking production planning and scheduling with maintenance, quality control, and financial data to provide a holistic view of refinery performance.

- Asset Performance Management (APM): Integrating maintenance schedules, work orders, and real-time asset health data from IoT sensors to optimize reliability and minimize downtime of critical refinery equipment.

- Commodity Trading and Risk Management (CTRM): Providing tools to capture trades, manage positions, and analyze market and credit risk in real-time.

- Retail Network Management: Managing fuel pricing, inventory, sales data from POS systems, and dealer/franchisee relationships across a network of service stations.

- Environmental, Health, and Safety (EHS): Integrating modules for incident management, compliance tracking, and emissions monitoring to ensure adherence to strict regulations.

- Financials and Analytics: Providing a single source of financial truth, from complex hydrocarbon accounting and tax management to powerful analytics for data-driven decision-making.

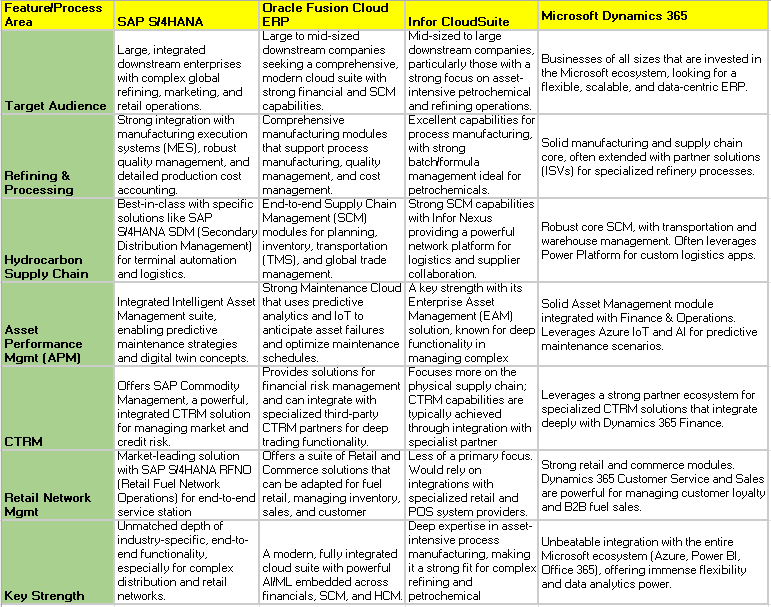

The ERP Showdown: A Comparative Look at Leading Solutions for Downstream

The ERP market offers powerful solutions, but for the downstream sector, the choice requires a deep understanding of industry-specific functionalities. Here’s how the leading ERP providers stack up for downstream oil and gas:

Making the Right Choice for Your Digital Future

The decision to invest in a new ERP is one of the most significant a downstream company can make. The right choice depends on your specific operational footprint and strategic priorities:

- For a large, vertically integrated company with extensive refining, logistics, and a branded retail network, SAP S/4HANA offers the most comprehensive, out-of-the-box solution to manage that complexity from end to end.

- For a growth-oriented company seeking a modern, all-in-one cloud platform to unify its financials, supply chain, and manufacturing, Oracle Fusion Cloud ERP presents a compelling, AI-driven alternative.

- For a petrochemical producer or refiner whose primary challenge is asset reliability and manufacturing efficiency, Infor CloudSuite provides best-in-class enterprise asset management and process manufacturing capabilities.

- For a company looking for a flexible, highly scalable platform that can leverage existing investments in the Microsoft ecosystem and harness the power of data analytics, Microsoft Dynamics 365 offers a powerful and adaptable foundation.

Ultimately, the goal is the same: to create a connected, intelligent, and resilient downstream enterprise. The journey from crude to customer is being redrawn by digital innovation, and the right ERP software is the engine that will power the industry leaders of tomorrow.

💌 Enjoyed this article?

If you found this post valuable, subscribe to my newsletter for more insights on digital transformation, AI, and business innovation.

👉 Subscribe to the newsletterOr let’s connect on LinkedIn — I share weekly content that’s practical for CIOs, CFOs, and transformation leaders.

🔗 Connect with me on LinkedIn