Flowing Forward: Digital Transformation in the Oil and Gas Midstream Sector with ERP

2025-06-18 · By Anil Kancharla · 8 min read

❤️ 0 Likes · 👁️ 0 Views

Flowing Forward: Digital Transformation in the Oil and Gas Midstream Sector with ERP

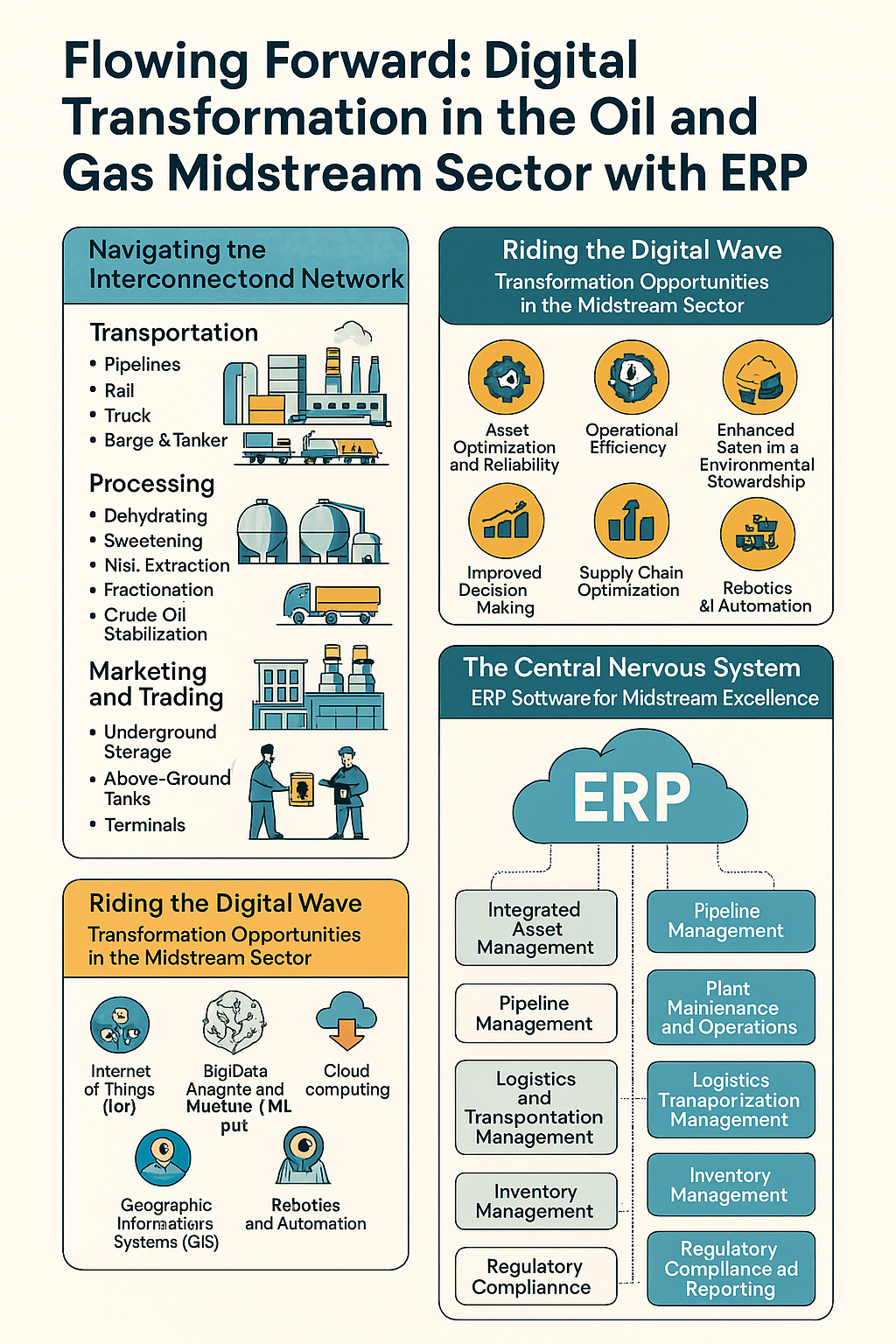

The oil and gas industry is a complex interconnected web, and while the upstream sector focuses on discovery and extraction, the midstream segment plays a crucial, often underappreciated, role. Located squarely between the wellhead and the refinery or distribution network, midstream operations are the vital arteries that transport, process, store, and market the raw hydrocarbons extracted from the earth. This intricate network is facing unprecedented pressures to enhance efficiency, ensure safety, and adapt to evolving market demands. The answer to these challenges, and the key to unlocking future growth, lies in embracing digital transformation, with Enterprise Resource Planning (ERP) software serving as a cornerstone for this evolution. This comprehensive blog post will delve into the complexities of the oil and gas midstream process, explore the significant opportunities presented by digital transformation, and provide a comparative analysis of leading ERP solutions designed to empower midstream operators. Navigating the Interconnected Network: Understanding the Midstream Process The midstream sector encompasses a wide range of activities essential for bridging the gap between upstream production and downstream refining and distribution. These activities can be broadly categorized as follows:

Transportation:

This is arguably the most visible aspect of the midstream sector. It involves the movement of crude oil, natural gas, and natural gas liquids (NGLs) from production sites to processing plants, storage facilities, and ultimately to refineries, export terminals, or end-users. Standard modes of transportation include:

Pipelines: The backbone of midstream transportation, pipelines provide a cost-effective and efficient means of moving large volumes of hydrocarbons over long distances. This includes gathering lines (small-diameter pipes that collect from wells), transmission pipelines (large-diameter, long-haul lines), and distribution pipelines (which feed into local markets).

Rail: Primarily used for crude oil and some natural gas liquids (NGLs), rail transport offers flexibility in reaching areas not directly served by pipelines.

Truck: Used for shorter distances and smaller volumes, particularly for initial gathering from well sites or delivery to local storage. Barge and Tanker: Essential for transporting large quantities of crude oil and refined products over waterways and oceans.

Processing:

Raw natural gas extracted from wells often contains impurities like water vapor, carbon dioxide, hydrogen sulfide, and heavier hydrocarbons (NGLs). Processing plants remove these impurities to produce pipeline-quality natural gas and separate valuable natural gas liquids (NGLs), including propane, butane, and ethane. Key processing activities include:

Dehydration: Removing water vapor to prevent corrosion and hydrate formation in pipelines. Sweetening: Removing acidic gases like hydrogen sulfide and carbon dioxide.

NGL Extraction: Utilizing various separation techniques to recover valuable natural gas liquids.

Fractionation: Further separating the extracted NGLs into individual components.

Crude Oil Stabilization: Removing volatile components from crude oil to make it safer and easier to transport and store.

Storage:

Strategic storage facilities are crucial for managing fluctuations in supply and demand, ensuring consistent delivery, and capitalizing on market opportunities. Storage facilities can include: Underground Storage: Typically, salt caverns or depleted reservoirs are used for large-volume storage of natural gas and NGLs. Above-Ground Tanks: Used for crude oil, NGLs, and refined products at terminals and processing plants. Terminals: Integrated facilities that combine storage, transportation infrastructure (pipelines, rail, marine), and blending capabilities.

Marketing and Trading:

Midstream companies often play a role in the marketing and trading of the hydrocarbons they handle, optimizing logistics, managing inventory, and facilitating transactions between producers and end-users.

Riding the Digital Wave: Transformation Opportunities in the Midstream Sector

The midstream sector, while vital, often operates on tight margins and faces increasing scrutiny regarding safety and environmental impact. Digital transformation offers a powerful pathway to address these challenges and unlock significant value.

Key Drivers for Digital Transformation in Midstream:

Asset Optimization and Reliability: Midstream infrastructure, particularly pipelines and processing plants, represents a significant capital investment. Digital technologies can enhance asset monitoring, predict failures, and optimize maintenance schedules, reducing downtime and extending asset life.

Operational Efficiency: Streamlining workflows, automating manual processes, and enhancing data visibility can lead to substantial cost reductions and increased throughput.

Enhanced Safety and Environmental Stewardship: Real-time monitoring of pipeline integrity, leak detection systems, and environmental sensors can help prevent accidents, minimize environmental impact, and ensure regulatory compliance.

Improved Decision-Making: Access to integrated data and advanced analytics enables better forecasting, optimized scheduling, and more informed commercial decisions.

Supply Chain Optimization: Efficiently managing the flow of hydrocarbons from the wellhead to the end user requires seamless coordination and visibility across the entire midstream value chain.

Impact of Emerging Technologies:

Internet of Things (IoT) and Sensors: Deploying sensors across pipelines, processing plants, and storage facilities provide real-time data on pressure, temperature, flow rates, equipment health, and environmental conditions.

Big Data Analytics and Machine Learning (ML): Analyzing the vast amounts of data generated by IoT devices and other sources can identify patterns, predict anomalies, optimize processes, and improve decision-making. For example, ML algorithms can predict pipeline corrosion or optimize compressor station performance.

Digital Twins: Creating virtual replicas of physical assets enables simulation, scenario planning, and predictive maintenance, thereby reducing the need for physical inspections and interventions.

Cloud Computing: Provides the scalable and cost-effective infrastructure needed to store, process, and analyze the large datasets generated by midstream operations.

Geographic Information Systems (GIS): Crucial for managing the vast network of pipelines and related infrastructure, providing spatial awareness for planning, maintenance, and safety.

Robotics and Automation: Implementing robotic inspection tools for pipelines and automating tasks in processing plants can improve safety and efficiency.

The Central Nervous System: ERP Software for Midstream Excellence

Enterprise Resource Planning (ERP) software serves as an integrated platform that connects the diverse operations of a midstream company, breaking down data silos and providing a single source of truth. A well-implemented ERP system tailored for the oil and gas midstream sector can drive significant improvements across the organization.

Key Benefits of ERP in the Midstream Sector:

Integrated Asset Management: Track the lifecycle of critical assets like pipelines, compressors, and processing equipment, schedule maintenance, manage work orders, and analyze asset performance.

Pipeline Management: Manage pipeline integrity, track flow rates and volumes, monitor custody transfers, and integrate with GIS systems for spatial visualization.

Plant Maintenance and Operations: Plan and schedule maintenance activities, manage equipment downtime, track inventory of spare parts, and monitor plant performance.

Logistics and Transportation Management: Optimize transportation scheduling, track shipments via pipelines, rail, or truck, manage contracts with carriers, and ensure timely delivery.

Inventory Management: Track the storage and movement of crude oil, natural gas, NGLs, and refined products across various storage facilities and terminals.

Financial Management and Accounting: Manage complex revenue recognition (including transportation tariffs and processing fees), track costs, handle joint venture accounting, and ensure regulatory compliance.

Supply Chain Management: Optimize procurement of materials and services, manage vendor relationships, and ensure efficient inventory levels.

Regulatory Compliance and Reporting: Streamline the collection and reporting of data related to environmental regulations, safety standards, and transportation tariffs.

Contract Management: Manage complex transportation, processing, storage, and marketing contracts.

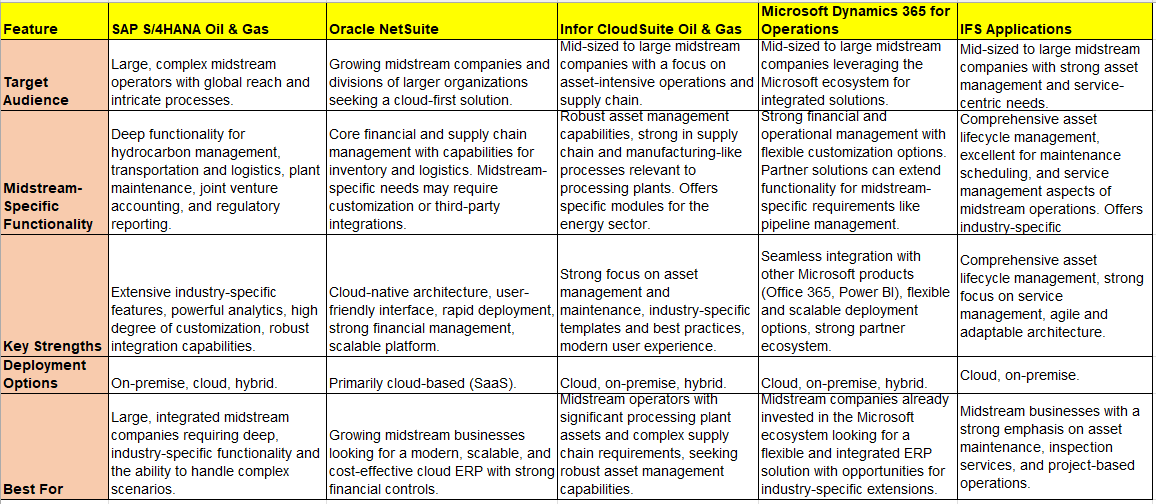

Comparing the Flow: Key ERP Solutions for the Midstream Sector

Choosing the right ERP system is a critical decision for midstream companies. Several leading vendors offer solutions that can be tailored to the specific needs of this sector. Here's a comparative look at some prominent options:

Considerations for ERP Selection in Midstream:

When evaluating ERP systems, midstream companies should consider the following:

Hydrocarbon Management: Does the system adequately handle the unique aspects of tracking, valuing, and accounting for oil and gas?

Asset Management Capabilities: How well does the system manage the lifecycle of pipelines, processing plants, and other critical infrastructure?

Logistics and Transportation: Can the system effectively manage complex transportation schedules and track movements across various modes?

Regulatory Compliance: Does the system help ensure adherence to relevant environmental, safety, and transportation regulations?

Integration Capabilities: Can the ERP system seamlessly integrate with existing midstream-specific technologies like SCADA systems, GIS, and pipeline integrity management software?

Scalability and Flexibility: Can the system adapt to the company's future growth and changing business needs?

Total Cost of Ownership: Consider not only the initial software licensing costs but also implementation, customization, training, and ongoing maintenance expenses.

Powering the Flow of the Future: Embracing Digital Transformation with ERP

The oil and gas midstream sector stands at a pivotal point. The increasing demand for efficiency, safety, and sustainability necessitates a fundamental shift towards digital operations. ERP software, with its ability to integrate data, automate processes, and provide real-time visibility, is a crucial enabler of this transformation. By strategically selecting and implementing the right ERP solution, midstream companies can optimize their operations, enhance asset reliability, improve safety and environmental performance, and ultimately ensure the continued flow of energy that powers our world. The digital future of the midstream is not just about technology; it's about building a more efficient, resilient, and sustainable energy infrastructure for generations to come.

💌 Enjoyed this article?

If you found this post valuable, subscribe to my newsletter for more insights on digital transformation, AI, and business innovation.

👉 Subscribe to the newsletterOr let’s connect on LinkedIn — I share weekly content that’s practical for CIOs, CFOs, and transformation leaders.

🔗 Connect with me on LinkedIn