The Future of Protein: How Digital Transformation and ERP are Revolutionizing Animal Production and Aquaculture

2025-07-24 · By Anil Kancharla · 8 min read

❤️ 0 Likes · 👁️ 0 Views

AI-generated image for illustration purposes only.

AI-generated image for illustration purposes only.

The Future of Protein: How Digital Transformation and ERP are Revolutionizing Animal Production and Aquaculture

AI-generated image for illustration purposes only.

AI-generated image for illustration purposes only.

In the heart of our global food system, the animal production and aquaculture industries are facing a pivotal moment. As of mid-2025, the challenge is immense: to provide safe, sustainable, and affordable protein for a growing global population while navigating unprecedented pressures. From intense biosecurity threats and stringent animal welfare regulations to labor shortages and consumer demands for greater transparency, the traditional models of farming are being stretched to their limits.

The solution lies not in expanding old methods, but in embracing a smarter, more connected future. Digital transformation is no longer a niche concept; it is the most critical driver of efficiency, sustainability, and profitability in modern protein production. At the core of this technological revolution is the Enterprise Resource Planning (ERP) system, a powerful digital platform that serves as the brain and central nervous system for the modern livestock farm and fish hatchery.

This in-depth blog post will explore the complex worlds of terrestrial and aquatic animal farming, uncover the game-changing opportunities of digital transformation, and provide a comparative analysis of leading ERP solutions designed to empower the protein producers of tomorrow.

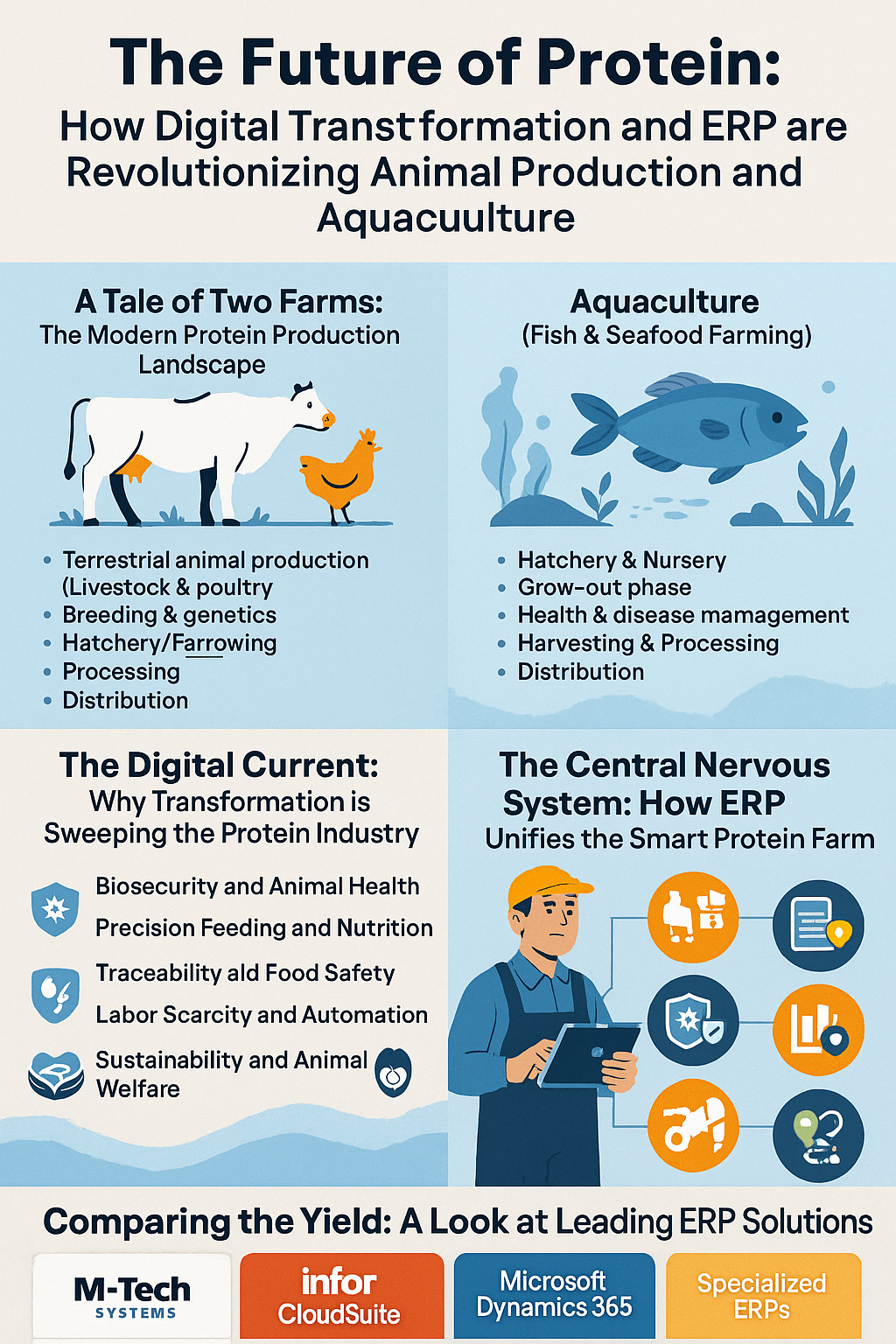

A Tale of Two Farms: The Modern Protein Production Landscape

While one is on land and the other in water, the core challenges and goals of modern animal production and aquaculture are remarkably similar.

1. Terrestrial Animal Production (Livestock & Poultry): This sector encompasses the raising of animals like cattle, swine, and poultry (chickens, turkeys). The lifecycle is a highly managed process:

- Breeding & Genetics: Selecting for desirable traits like rapid growth, disease resistance, and high yield.

- Hatchery/Farrowing: The earliest life stage, requiring precise environmental control.

- Grow-Out Phase: Raising animals to market weight, where feed management, health monitoring, and environmental conditions are paramount. This is where the crucial Feed Conversion Ratio (FCR)—the measure of an animal's efficiency in converting feed mass into body mass—is optimized.

- Processing: Transporting animals to processing plants where they are prepared for distribution.

- Distribution: Moving finished protein products through a cold chain to retailers, restaurants, and consumers.

2. Aquaculture (Fish & Seafood Farming): The "blue revolution," aquaculture is the farming of fish, crustaceans, mollusks, and aquatic plants. The process involves:

- Hatchery & Nursery: Breeding and raising fry (young fish) or spat (young shellfish) in controlled tanks.

- Grow-Out Phase: Transferring the young stock to larger systems—such as ponds, net pens in the ocean, or advanced Recirculating Aquaculture Systems (RAS)—to grow to harvest size. Water quality, oxygen levels, temperature, and feed management are critical variables.

- Health & Disease Management: Monitoring for and treating diseases, a constant challenge in dense aquatic populations.

- Harvesting & Processing: Collecting the market-sized fish or seafood and processing it for sale (e.g., filleting, freezing).

- Distribution: Like its terrestrial counterpart, ensuring product integrity through a temperature-controlled supply chain.

The Digital Current: Why Transformation is Sweeping the Protein Industry

In 2025, the pressure to modernize is intense. Digital transformation offers a powerful suite of tools to address the industry's most pressing challenges.

- Biosecurity and Animal Health: In an interconnected world, the threat of disease wiping out entire flocks, herds, or stocks is a primary concern. Digital tools enable real-time health monitoring, early disease detection, and precise control over environmental factors, forming a powerful defense against outbreaks.

- Precision Feeding and Nutrition: Feed is the single largest cost in protein production. Digital systems allow for precision feeding, delivering customized nutritional formulas based on an animal's specific life stage, weight, and health data, thereby optimizing the FCR and dramatically reducing costs and waste.

- Traceability and Food Safety: Consumers and regulators demand to know the full story of their food. Digital traceability, often powered by blockchain and ERP, creates an immutable record of an animal's journey from birth/hatchery to the dinner plate, ensuring safety and building consumer trust.

- Labor Scarcity and Automation: Finding and retaining skilled labor is a major hurdle. Automated feeding systems, robotic cleaners, and AI-powered monitoring reduce the reliance on manual labor, allowing staff to focus on higher-value tasks.

- Sustainability and Animal Welfare: Technology provides the data to prove and improve sustainable practices. Sensors can monitor water quality in aquaculture to minimize environmental impact, while cameras and acoustic sensors can monitor animal behavior to ensure welfare standards are being met.

The Technologies Powering the Digital Farm:

- Internet of Things (IoT): A network of sensors provides real-time data. In barns, this means tracking air quality, temperature, and humidity. In aquaculture tanks, it means monitoring pH, oxygen levels, and salinity. Wearable sensors on individual animals can track activity levels and vital signs.

- Artificial Intelligence (AI) and Machine Learning: AI algorithms analyze data from sensors and cameras to predict disease outbreaks, optimize feed schedules, identify individual animals, and monitor behavior for signs of stress or illness.

- Robotics and Automation: Automated feeders, robotic pen cleaners, and autonomous water monitoring drones are streamlining daily tasks and improving consistency.

- Blockchain: Provides a secure and transparent ledger for farm-to-fork traceability, making it virtually impossible to tamper with data related to an animal's history.

The Central Nervous System: How ERP Unifies the Smart Protein Farm

With data flowing from countless sensors, automated systems, and daily operations, how does a producer turn this flood of information into profitable action? This is the mission-critical role of an Enterprise Resource Planning (ERP) system designed specifically for animal production and aquaculture.

An Ag-ERP acts as the digital hub, integrating every piece of data into a single, unified platform. It connects the barn, the pond, the feed mill, and the front office.

Core Benefits of an ERP for Protein Production:

- Flock/Herd/Stock Management: Provides a complete view of every animal group, tracking population, mortality rates, growth curves, and movements between houses or tanks.

- Feed Management and Formulation: Manages feed inventory, optimizes formulations for cost and nutrition, and calculates FCR in real-time to measure performance.

- Health and Biosecurity Command Center: Schedules and records vaccinations and treatments, monitors environmental data against health thresholds, and maintains a complete medical history for auditing and compliance.

- Processing and Yield Analysis: Connects farm performance directly to processing plant outcomes. It tracks carcass or fillet yields against live weight, calculating true profitability per animal or flock.

- Full-Chain Traceability: The backbone of any traceability program, an ERP can track a batch of feed to a specific flock, which is then tracked to a specific set of finished products, complete with production dates and shipping information.

- Financial Integration: All operational data feeds directly into the financial modules, providing a real-time understanding of the cost of production and the profitability of each cycle.

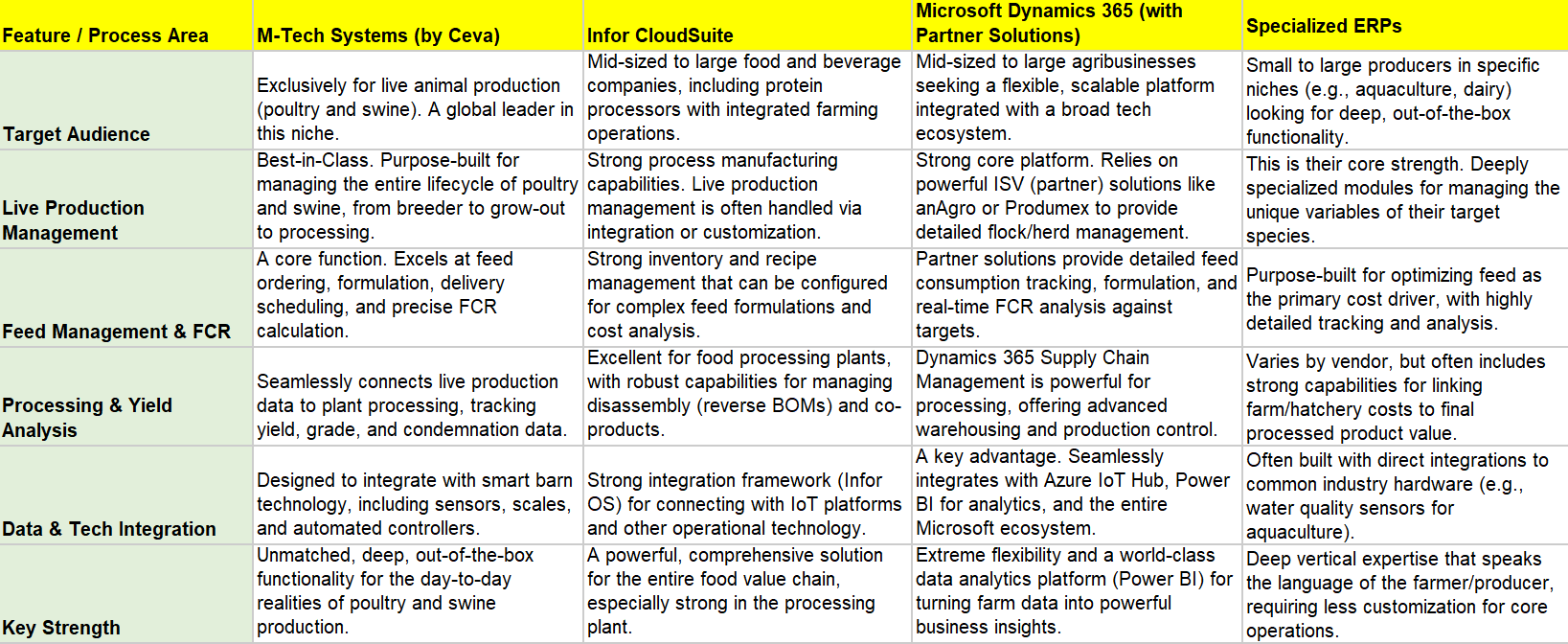

Comparing the Yield: A Look at Leading ERP Solutions

Choosing an ERP is a major investment. The market offers powerful platforms with deep, industry-specific functionality. Here’s how some of the leading solutions stack up for animal production and aquaculture in 2025.

Cultivating the Protein of the Future

The path forward for animal production and aquaculture is clear: it is digital, data-driven, and sustainable. The companies that will lead this new era are those that embrace technology to gain a complete, real-time understanding of their operations.

- For poultry and swine producers seeking the most comprehensive, purpose-built solution for managing their live operations, M-Tech Systems is the industry standard.

- For large, integrated protein companies that need a powerful ERP to manage both processing and farming, Infor CloudSuite offers a robust, end-to-end solution.

- For innovative agribusinesses wanting to build a flexible, data-centric technology stack and leverage best-in-class analytics, Microsoft Dynamics 365 provides a powerful and adaptable foundation.

- For producers in highly specialized niches like aquaculture, dedicated ERPs offer tailored functionality that understands their unique operational challenges right out of the box.

By implementing the right ERP, producers are not just buying software. They are investing in a more resilient, transparent, and profitable future, ensuring they can continue to fulfill their essential role in feeding the world.

💌 Enjoyed this article?

If you found this post valuable, subscribe to my newsletter for more insights on digital transformation, AI, and business innovation.

👉 Subscribe to the newsletterOr let’s connect on LinkedIn — I share weekly content that’s practical for CIOs, CFOs, and transformation leaders.

🔗 Connect with me on LinkedIn