The Recipe for Success: Mastering the Food Manufacturing Process with Digital Transformation and ERP

2025-07-03 · By Anil Kancharla · 6 min read

❤️ 0 Likes · 👁️ 0 Views

The Recipe for Success: Mastering the Food Manufacturing Process with Digital Transformation and ERP

The journey of food from farm to fork is one of the world's most essential and complex processes. The food manufacturing sector, the engine at the heart of this journey, is a dynamic and high-stakes environment. Today, manufacturers face a perfect storm of challenges: razor-thin margins, ever-stricter food safety regulations, complex global supply chains, and a new generation of consumers demanding greater transparency and sustainability.

In this demanding landscape, clinging to outdated manual processes and siloed systems is a recipe for disaster. The key to not just surviving but thriving lies in embracing digital transformation. At the core of this evolution is a technology that acts as the central nervous system for the modern food manufacturer: Enterprise Resource Planning (ERP) software.

This comprehensive blog post will dissect the intricate food manufacturing process, explore the game-changing opportunities of digital transformation, and provide an in-depth comparative analysis of leading ERP solutions designed to help food and beverage companies achieve a new level of success.

🥦 From Raw Ingredients to Ready-to-Eat: The Modern Food Manufacturing Process

The transformation of raw agricultural products into the safe, delicious, and convenient foods that line our grocery store shelves is a marvel of modern industry. While specific steps vary by product, the general process flow includes several critical stages: Sourcing and Procurement It all begins with acquiring high-quality raw materials. This involves managing relationships with growers, farmers, and suppliers, negotiating contracts, and ensuring that all incoming ingredients meet strict quality and safety specifications.

Raw Material Management Once on-site, perishable ingredients must be properly stored, managed, and tracked. This includes monitoring temperature, humidity, and shelf life to prevent spoilage and ensure "First-In, First-Out" (FIFO) or "First-Expired, First-Out" (FEFO) inventory rotation.

Processing and Production

- Mixing/Blending: Combining ingredients according to precise recipes or formulas.

- Cooking/Baking/Pasteurizing: Applying thermal processes to ensure safety and achieve desired textures and flavors.

- Cutting/Forming/Grinding: Physically altering ingredients to create the final product form.

- Fermentation: Using microorganisms to create products like yogurt, cheese, and bread.

Quality Control and Assurance At every stage, rigorous quality checks are paramount. This involves testing for contaminants, verifying nutritional content, checking for allergens, and ensuring that every batch meets both internal standards and regulatory requirements.

Packaging and Labeling Packaging serves to protect the product, extend its shelf life, and provide consumers with vital information. This stage is critical for ensuring accurate ingredient lists, nutritional facts, allergen warnings, and date codes.

Warehousing and Distribution Finished goods are stored in controlled environments before being shipped to distributors, retailers, or directly to consumers. This final logistical step is crucial for getting products to market quickly and safely.

📈 The Digital Feast: Why Transformation is on Every Manufacturer's Menu

The food manufacturing industry is at a digital tipping point. The pressures are immense, but so are the opportunities for those who embrace technology.

Key Drivers:

- Food Safety & Traceability In an era of heightened consumer awareness and stringent regulations like the FDA's Food Safety Modernization Act (FSMA), the ability to rapidly trace a product from farm to fork is non-negotiable. Digital systems provide the granular, real-time tracking needed to manage recalls effectively and ensure consumer safety.

- Supply Chain Resilience As seen in recent years, global supply chains are fragile. Digital tools offer greater visibility, helping manufacturers anticipate disruptions, manage inventory more effectively, and diversify their sourcing strategies.

- Efficiency & Waste Reduction Manual processes lead to errors, inefficiencies, and waste—a critical issue when dealing with perishable goods. Automation and data analytics help optimize production schedules, improve yield, and reduce spoilage.

- Transparency & Consumer Trust Today's consumers want to know more about their food—where it comes from, what's in it, and its environmental impact. Digital platforms enable the transparency needed to build consumer trust and loyalty.

- Labor Optimization via Automation With a persistent shortage of skilled labor, automation and streamlined digital workflows are essential to maintaining productivity and meeting production targets.

🧠 The Central Ingredient: How ERP Software Powers Food Manufacturing

To tackle these challenges and capitalize on digital opportunities, manufacturers need a single, unified source of truth. An Enterprise Resource Planning (ERP) system designed specifically for the food and beverage industry provides this foundation, integrating every aspect of the operation into a cohesive whole.

Core ERP Capabilities:

- ✅ End-to-End Traceability Instantly track every ingredient and finished product by lot and batch number, from receiving to shipping, enabling swift and precise recalls.

- ✅ Recipe & Formula Management Securely manage complex recipes, control versions, scale batches, and analyze costs and nutritional information for every product.

- ✅ Inventory & Shelf-Life Automate inventory control using FEFO principles, manage products with variable shelf lives, and reduce waste from expired ingredients.

- ✅ Quality & Compliance Integrate quality checks directly into the production process, enforce safety protocols, and maintain a digital audit trail to simplify compliance with FSMA, HACCP, and other standards.

- ✅ Production Scheduling Optimize production runs based on demand forecasts, ingredient availability, and equipment capacity to maximize efficiency and minimize downtime.

- ✅ Allergen Management Track allergens throughout the production process to prevent cross-contamination and ensure accurate labeling.

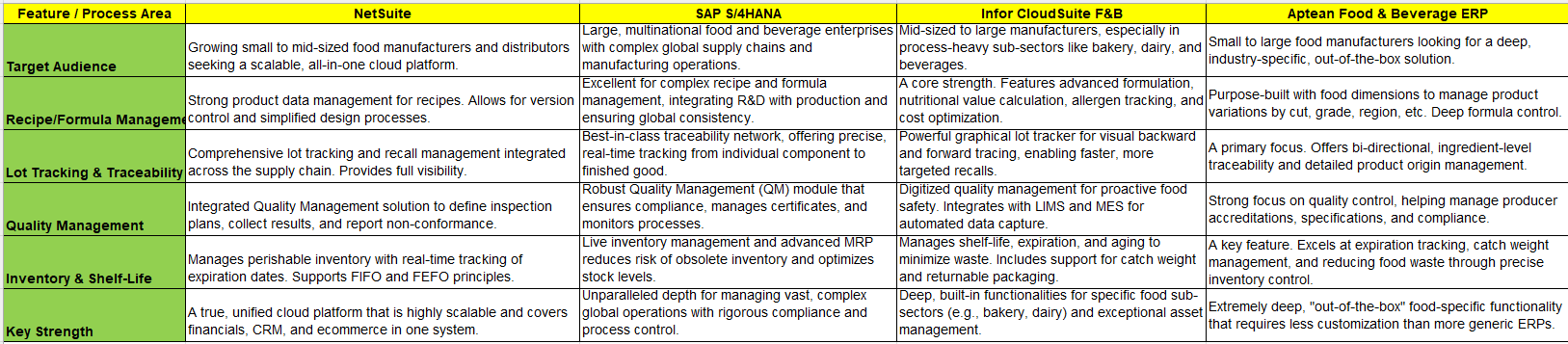

🧾 ERP Menu: Comparative Analysis

Choosing the right ERP is a critical strategic decision. Here’s a comparative analysis of top ERP solutions tailored for the food and beverage industry:

🧭 Choosing Your Recipe for Digital Success

The right ERP solution is the cornerstone of a successful digital transformation strategy. Your choice should align with your company's size, complexity, and strategic goals.

-

For fast-growing, agile food companies that need a scalable, all-in-one cloud solution to manage their entire business, NetSuite offers a powerful and unified platform.

-

For large, global enterprises managing complex supply chains and stringent regulatory demands across multiple countries, SAP S/4HANA provides unmatched depth and control.

-

For manufacturers in specific process-heavy industries like baking or dairy that need deep functionality tailored to their unique production methods, Infor CloudSuite Food & Beverage is a leading contender.

-

For companies that want a purpose-built solution with rich, out-of-the-box features designed exclusively for food manufacturing, minimizing the need for extensive customization, Aptean Food & Beverage ERP is an excellent choice.

The food manufacturing industry is in the midst of a profound transformation. The companies that will lead the future are those that invest in the digital tools to become more agile, transparent, and efficient. By implementing a robust, industry-specific ERP system, you are not just buying software; you are investing in a recipe for lasting success in a rapidly evolving world.

💌 Enjoyed this article?

If you found this post valuable, subscribe to my newsletter for more insights on digital transformation, AI, and business innovation.

👉 Subscribe to the newsletterOr let’s connect on LinkedIn — I share weekly content that’s practical for CIOs, CFOs, and transformation leaders.

🔗 Connect with me on LinkedIn