Navigating the Depths: A Guide to the Upstream Oil and Gas Process and its Digital Revolution with ERP Software

2025-06-11 · By Anil Kancharla · 9 min read

❤️ 1 Likes · 👁️ 0 Views

🛢️ Navigating the Depths: A Guide to the Upstream Oil and Gas Process and its Digital Revolution with ERP Software

The global energy landscape is in a constant state of flux. As the world's demand for energy continues to evolve, the oil and gas industry remains a critical player. The upstream sector, the starting point of the entire oil and gas value chain, is where the hunt for and extraction of hydrocarbons begins. This complex and capital-intensive process is undergoing a profound transformation, driven by the imperative for greater efficiency, cost reduction, and enhanced safety. At the heart of this evolution lies digital transformation, with Enterprise Resource Planning (ERP) software emerging as a pivotal technology to navigate the challenges and seize the opportunities of this new era.

This in-depth blog post will explore the intricacies of the upstream oil and gas process, delve into the compelling opportunities for digital transformation, and provide a comparative analysis of leading ERP solutions designed to empower upstream operations.

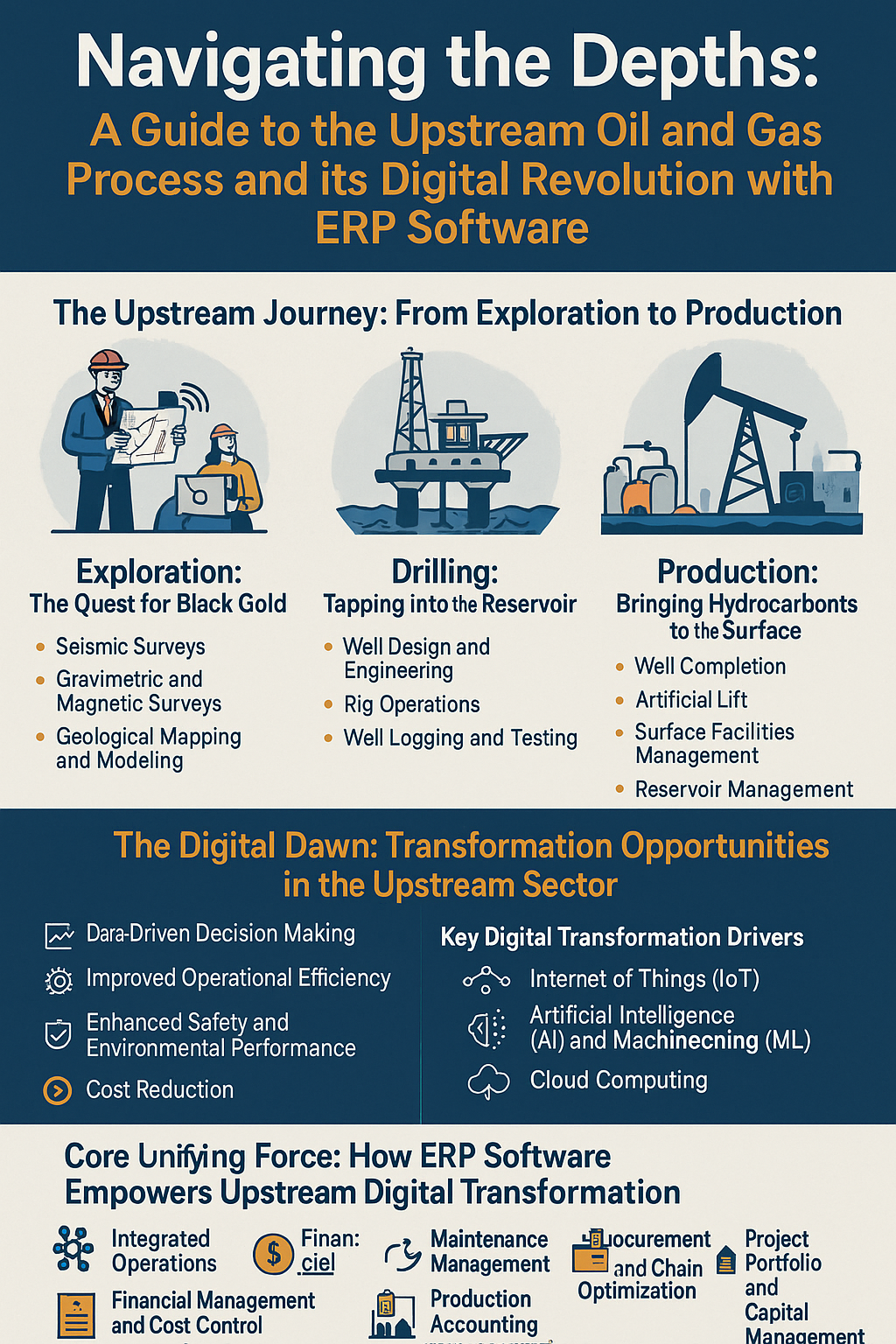

🔍 The Upstream Journey: From Exploration to Production

The upstream sector of the oil and gas industry is fundamentally about exploration and production (E&P). It's a high-risk, high-reward endeavor that can be broken down into three primary stages:

1. Exploration: The Quest for Black Gold

This initial phase is all about identifying potential hydrocarbon reservoirs beneath the earth's surface. Geologists and geophysicists employ sophisticated techniques to pinpoint promising locations. This includes:

- Seismic Surveys: Generating and analyzing seismic waves to create detailed images of subsurface rock formations.

- Gravimetric and Magnetic Surveys: Measuring variations in the Earth's gravitational and magnetic fields to identify geological structures that might trap oil and gas.

- Geological Mapping and Modeling: Studying rock samples and surface geology to understand the potential for hydrocarbon accumulation.

The exploration phase is fraught with uncertainty, and its success hinges on the accuracy of data analysis and interpretation.

2. Drilling: Tapping into the Reservoir

Once a potential reservoir is identified and deemed commercially viable, the drilling phase commences. This involves boring deep into the earth to access the trapped hydrocarbons. Drilling operations are complex and require meticulous planning and execution. Key aspects include:

- Well Design and Engineering: Creating a detailed plan for the well, including its trajectory, casing design, and drilling fluid program.

- Rig Operations: Managing the drilling rig and its various components to ensure safe and efficient drilling.

- Well Logging and Testing: Collecting data from the wellbore to evaluate the characteristics of the reservoir and the fluids it contains.

Drilling is a high-cost activity, and any inefficiencies or non-productive time can have a significant financial impact.

3. Production: Bringing Hydrocarbons to the Surface

With a successful well drilled, the production phase begins. This involves extracting the oil and gas from the reservoir and preparing it for transportation to midstream facilities. Key activities in this stage include:

- Well Completion: Installing the necessary equipment in the wellbore to control the flow of hydrocarbons.

- Artificial Lift: Employing techniques like gas lift or electric submersible pumps to bring oil to the surface when natural reservoir pressure is insufficient.

- Surface Facilities Management: Operating and maintaining the equipment at the wellhead and in the field to separate oil, gas, and water, and to treat them to meet transportation specifications.

- Reservoir Management: Monitoring the performance of the reservoir over time and implementing strategies to maximize hydrocarbon recovery.

The production phase is a long-term endeavor that requires continuous optimization to ensure sustained output and profitability.

🌐 The Digital Dawn: Transformation Opportunities in the Upstream Sector

The upstream oil and gas industry has traditionally been characterized by its reliance on heavy machinery and manual processes. However, the tide is turning. The convergence of volatile commodity prices, increasing regulatory scrutiny, and the availability of powerful new technologies is accelerating the adoption of digital solutions. Digital transformation offers a wealth of opportunities to address the sector's most pressing challenges and unlock new levels of performance.

Key Digital Transformation Drivers:

- 📊 Data-Driven Decision Making: The upstream process generates vast amounts of data from seismic surveys, drilling operations, and production facilities. Digital technologies enable companies to collect, process, and analyze this data to make more informed and timely decisions.

- ⚙️ Improved Operational Efficiency: Automation and remote monitoring capabilities can streamline workflows, reduce manual intervention, and minimize downtime.

- 🛡️ Enhanced Safety & Environmental Performance: Real-time monitoring of equipment and environmental conditions can help prevent accidents and ensure compliance with regulations.

- 💸 Cost Reduction: By optimizing production, reducing non-productive time, and improving asset management, digital technologies can significantly lower operating costs.

The Role of Emerging Technologies:

- 🌐 Internet of Things (IoT): Sensors deployed on drilling rigs, pipelines, and other equipment can collect real-time data on performance, condition, and environmental parameters.

- 🤖 Artificial Intelligence (AI) & Machine Learning (ML): AI and ML algorithms can analyze vast datasets to identify patterns, predict equipment failures, optimize drilling parameters, and improve reservoir characterization.

- ☁️ Cloud Computing: Cloud platforms provide a scalable and cost-effective way to store, process, and analyze the massive volumes of data generated in the upstream sector.

- 📈 Big Data Analytics: Advanced analytics tools enable companies to extract valuable insights from their data, leading to better decision-making and improved performance.

- 🧪 Digital Twins: Creating virtual replicas of physical assets allows for simulation, analysis, and optimization of performance in a risk-free environment.

🧠 The Unifying Force: How ERP Software Empowers Upstream Digital Transformation

Enterprise Resource Planning (ERP) software acts as the central nervous system for a digitalized upstream operation. It integrates data and processes from across the organization, providing a single source of truth and enabling seamless collaboration between different departments. A robust ERP system tailored for the oil and gas industry can revolutionize how upstream companies operate.

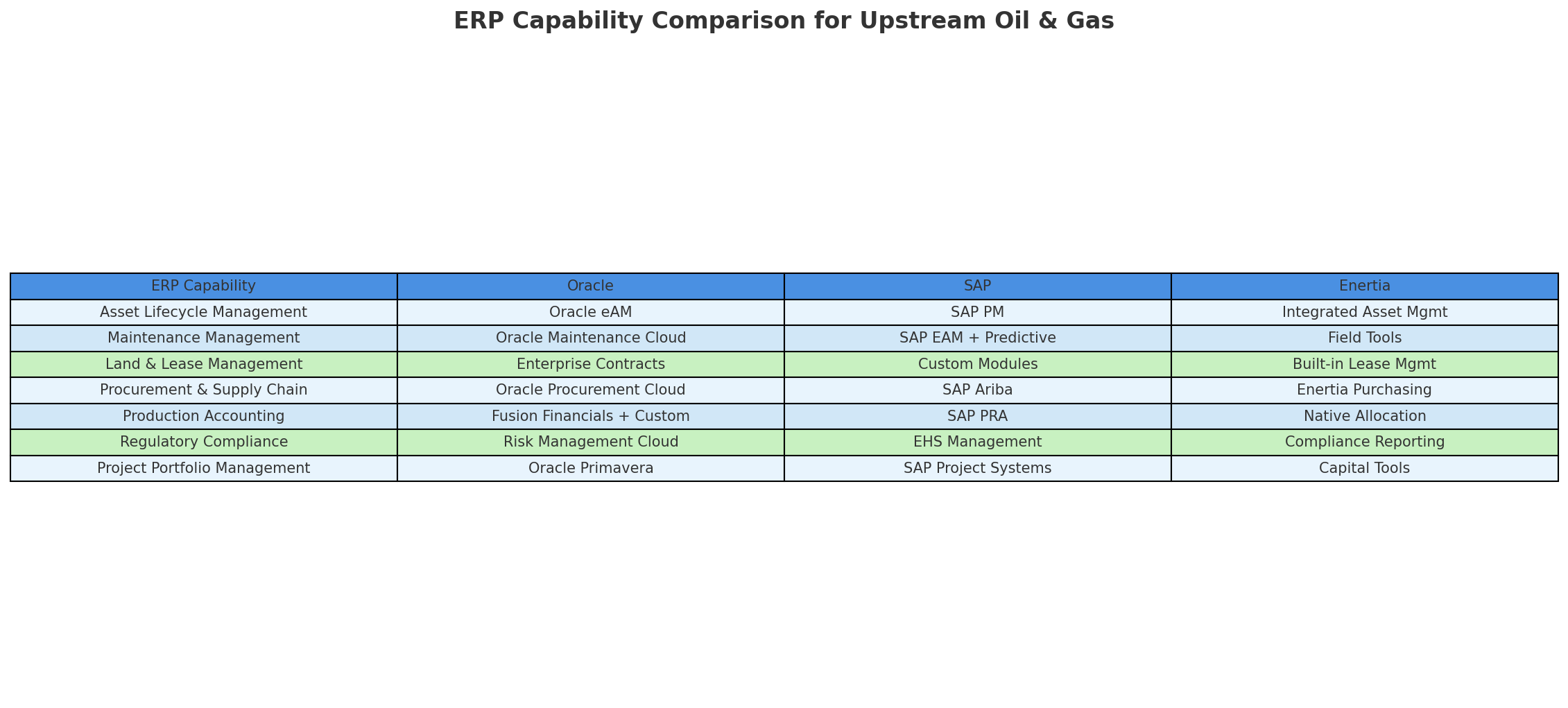

Core Benefits of ERP in the Upstream Sector:

- 🧩 Integrated Operations: ERP systems break down data silos between geology, drilling, production, finance, and supply chain, providing a holistic view of the entire upstream value chain.

- 💰 Financial Control & JIB Accounting: Track project costs in real-time, manage joint interest billing (JIB), and ensure accurate revenue accounting.

- 🛠️ Asset Lifecycle Management: With solutions like Oracle Enterprise Asset Management (eAM), companies can track and optimize the health, maintenance, and depreciation of rigs, pumps, and other critical assets. This leads to reduced downtime, better resource planning, and extended asset life.

- 🧾 Maintenance Management: Oracle Maintenance Cloud enables preventive and predictive maintenance strategies, integrates with IoT sensor data, and automates work orders to ensure high equipment availability.

- 📑 Land & Lease Administration: Managed within solutions like Oracle Enterprise Contracts and Enertia's upstream modules, this functionality tracks lease obligations, royalty payments, contract terms, and compliance milestones for leased oilfields and mineral rights.

- 🚚 Procurement Optimization: Oracle Procurement Cloud and SAP Ariba help streamline sourcing, manage supplier performance, automate PO workflows, and ensure timely delivery to remote or offshore locations.

- 🧮 Production Allocation: Specialized ERP modules (e.g., Enertia, SAP PRA) handle well-level allocation, partner splits, and reporting for regulatory and royalty purposes.

- 🔍 Regulatory Reporting: Automated tracking of HSE data, emissions, and regulatory submissions ensures upstream companies meet local and international compliance standards. Solutions like SAP Environment, Health, and Safety Management and Oracle Risk Management Cloud are often deployed.

- 📊 Project Portfolio Control : Oracle Primavera and SAP Project Systems integrate with ERP to manage drilling campaigns, capital expenditure planning, and project-based cost control.

This deeper integration of ERP with operational technologies ensures upstream companies are not only managing financial and logistical operations effectively but also optimizing field operations with real-time data and intelligent automation.

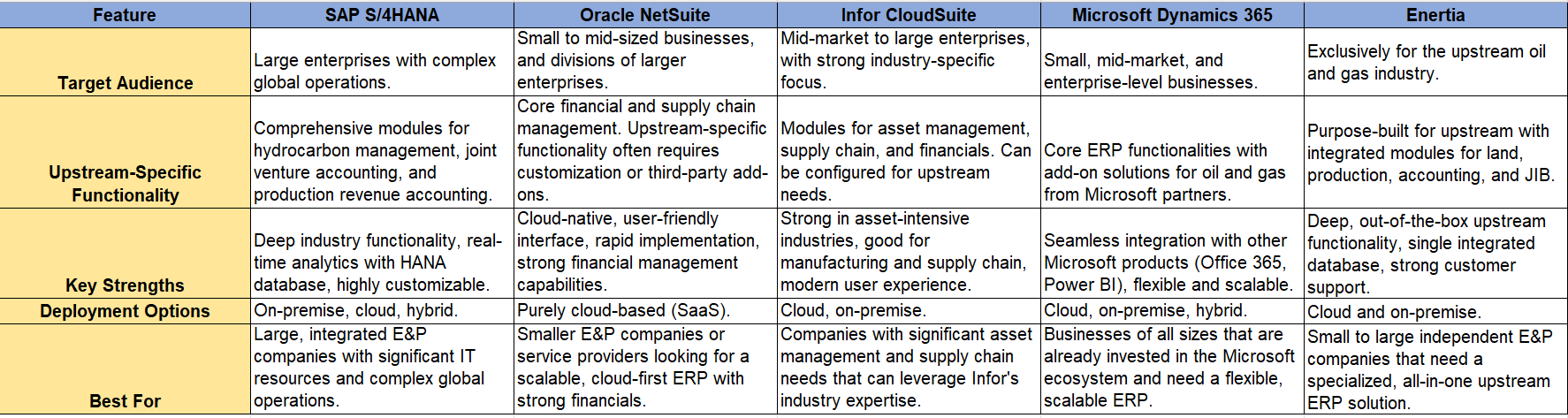

📊 A Comparative Look at Leading ERP Solutions for the Upstream Sector

The ERP market offers a range of solutions, each with its own strengths and focus. For upstream oil and gas companies, selecting the right ERP is a critical decision. Here's a comparative overview of some of the leading players:

In-Depth Look at Key Players:

- SAP S/4HANA: The go-to choice for the supermajors and large national oil companies, SAP S/4HANA offers unparalleled depth in its oil and gas-specific modules. Its real-time analytics capabilities, powered by the in-memory HANA database, provide powerful insights for optimizing complex upstream operations. However, its implementation can be complex and costly.

- Oracle NetSuite: As a cloud-native ERP, NetSuite offers a more agile and cost-effective solution for smaller and mid-sized upstream players. Its strengths lie in its robust financial management and the ability to scale as a company grows. While it may require more customization for highly specific upstream processes, its ease of use and rapid deployment are significant advantages.

- Infor CloudSuite: Infor has a strong reputation in asset-intensive industries, making it a viable contender for upstream companies. Its capabilities in enterprise asset management (EAM) are particularly relevant for managing drilling rigs, production platforms, and other critical equipment.

- Microsoft Dynamics 365: The power of the Microsoft ecosystem is a major draw for Dynamics 365. Its seamless integration with tools like Power BI for analytics and Office 365 for productivity can create a highly efficient work environment. The availability of partner-developed solutions for the oil and gas industry extends its capabilities for upstream operations.

- Enertia: Enertia stands out as a pure-play upstream ERP provider. Its entire suite of applications is designed specifically for the exploration and production lifecycle. This deep industry focus means that much of the required functionality is available out-of-the-box, reducing the need for extensive customization. For independent E&P companies, Enertia offers a compelling and comprehensive solution.

🔮 The Future is Digital: Embracing the Transformation

The upstream oil and gas industry is at a crossroads. The path forward lies in embracing digital transformation to unlock new efficiencies, enhance safety, and ensure long-term sustainability. ERP software is not just a tool for back-office administration; it is a strategic platform that can unify operations, empower data-driven decisions, and drive the digital revolution in the upstream sector.

By carefully evaluating their unique needs and selecting an ERP solution that aligns with their operational realities and strategic goals, upstream oil and gas companies can not only navigate the challenges of today but also thrive in the dynamic energy landscape of tomorrow. The journey from the depths of the earth to the digital frontier is well underway, and those who embrace the power of technology will be the ones to lead the charge.

💌 Enjoyed this article?

If you found this post valuable, subscribe to my newsletter for more insights on digital transformation, AI, and business innovation.

👉 Subscribe to the newsletterOr let’s connect on LinkedIn — I share weekly content that’s practical for CIOs, CFOs, and transformation leaders.

🔗 Connect with me on LinkedIn