Digging Deeper: How Digital Transformation and ERP are Reshaping the Mining Industry in 2025

2025-07-16 · By Anil Kancharla · 7 min read

❤️ 0 Likes · 👁️ 0 Views

AI-generated image for illustration purposes only.

AI-generated image for illustration purposes only.

Digging Deeper: How Digital Transformation and ERP are Reshaping the Mining Industry in 2025

AI-generated image for illustration purposes only.

AI-generated image for illustration purposes only.

The mining industry, a foundational pillar of the global economy, is at a critical inflection point. As we stand in mid-2025, the sector faces a complex matrix of challenges: relentless pressure to meet Environmental, Social, and Governance (ESG) standards, the operational reality of declining ore grades, persistent safety imperatives, and volatile global supply chains. The traditional playbook of simply digging more is no longer viable.

The future of mining, and indeed its very license to operate, hinges on a profound shift. This is the era of the "Smart Mine," an operation driven by digital transformation. It's a revolution that promises to make mining safer, more efficient, and critically, more sustainable. At the absolute core of this transformation lies the indispensable role of modern Enterprise Resource Planning (ERP) software, the digital backbone that connects every sensor, vehicle, and process into an intelligent, unified whole.

This in-depth blog post will explore the modern mining lifecycle, uncover the immense opportunities presented by digital transformation, and provide a comparative analysis of leading ERP solutions that are empowering mining companies to thrive in this new age.

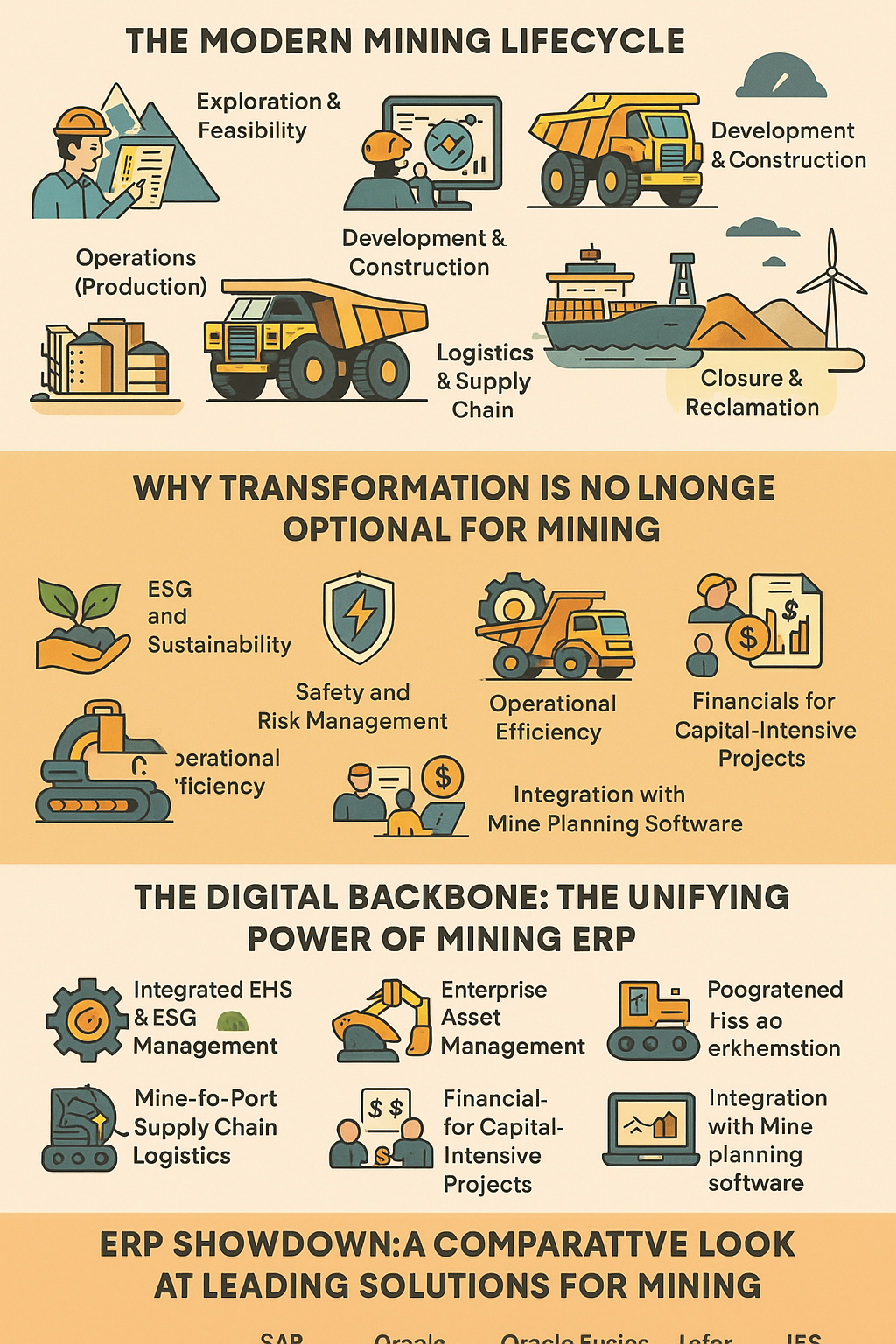

The Modern Mining Lifecycle: A Journey of Precision and Complexity

The perception of mining as a simple, brute-force operation is decades out of date. Today, it's a highly sophisticated, capital-intensive process that spans years, from initial discovery to final land restoration.

Exploration & Feasibility: Geologists use advanced remote sensing, seismic surveys, and AI-powered data analysis to identify potential deposits. This is followed by rigorous drilling and modeling to determine the ore body's size, grade, and economic viability.

Mine Planning & Design: Once a project is deemed feasible, engineers design the entire mine layout. This involves complex geological modeling and scheduling software to create a detailed life-of-mine plan that optimizes extraction sequences, ensuring safety and maximizing resource recovery.

Development & Construction: This stage involves building all necessary infrastructure, which can include access roads, processing plants, tailings storage facilities, and worker accommodation. It's a massive construction project that can take several years.

Operations (Production): This is the active extraction phase. For an open-pit mine, this involves drilling, blasting, and using colossal haul trucks and shovels to move ore and waste. In underground mining, it involves complex tunneling and material handling systems. The extracted ore is then transported to processing plants.

Processing: At the plant, ore is crushed, milled, and put through metallurgical processes (like flotation or leaching) to separate the valuable minerals from the waste rock (tailings).

Logistics & Supply Chain: The concentrated mineral product is transported—often via complex, multi-modal supply chains involving rail, trucks, and ships—to smelters, refiners, or end customers across the globe.

Closure & Reclamation: Once the ore body is depleted, the mine is decommissioned. This final, critical stage involves dismantling infrastructure and rehabilitating the land to a safe, stable, and often natural state, a process governed by strict environmental regulations.

The Digital Mandate: Why Transformation is No Longer Optional for Mining

The pressures on the mining sector in 2025 are immense, but technology offers powerful solutions to each of these challenges, creating unprecedented opportunities.

- ESG and Sustainability: Investors, regulators, and communities now demand transparent, verifiable proof of sustainable practices. Digital tools are essential for monitoring and reporting on water usage, energy consumption, carbon emissions, and land rehabilitation efforts.

- Safety and Risk Management: Mining remains a high-risk industry. Digital transformation, through remote operation of machinery, real-time personnel tracking, and AI-powered hazard detection, is fundamentally changing the safety paradigm, moving people out of harm's way.

- Operational Efficiency: With easily accessible, high-grade ore bodies becoming scarcer, miners must extract more value from every ton. Digital technologies enable precision mining, optimize fleet management, predict equipment failures, and streamline processes to reduce costs and maximize throughput.

- Asset Performance Management (APM): A single haul truck can cost over $5 million. Unplanned downtime is financially crippling. Predictive maintenance, powered by IoT sensors and AI, can anticipate failures before they happen, maximizing the availability and lifespan of critical assets.

- Supply Chain Visibility: Global disruptions have highlighted the fragility of supply chains. A connected digital ecosystem provides real-time visibility from the mine pit to the port, allowing for better planning, optimized logistics, and a more resilient supply network.

The Technologies Powering the Smart Mine:

- Internet of Things (IoT): Sensors embedded in equipment, processing plants, and even worker apparel collect vast streams of real-time data on everything from engine temperature and tire pressure to air quality and personnel location.

- AI and Machine Learning: Algorithms analyze data to optimize everything from drill and blast patterns to metallurgical processing formulas. AI powers predictive maintenance and can identify safety hazards from video feeds.

- Autonomous Fleets: Self-driving haul trucks, drills, and trains are already operational in many mines, improving safety, boosting productivity, and running 24/7.

- Digital Twins: A virtual, real-time replica of the entire mining operation—from the geology to the machinery and processing plant. It allows operators to simulate changes, optimize plans, and train personnel in a risk-free environment.

The Digital Backbone: The Unifying Power of Mining ERP

With a torrent of data flowing from autonomous trucks, IoT sensors, and geological models, how does a mining company unify this information to make coherent, strategic decisions? This is the mission-critical role of an Enterprise Resource Planning (ERP) system built for the mining industry.

A modern mining ERP acts as the central nervous system, integrating every facet of the operation into a single source of truth. It connects the pit to the C-suite, providing a holistic view of the entire business.

Core Benefits of a Mining ERP:

- Integrated EHS & ESG Management: Provides modules to track environmental data, manage safety incidents, ensure regulatory compliance, and automate the collection of data needed for transparent ESG reporting.

- Enterprise Asset Management (EAM/APM): Manages the entire lifecycle of multi-million-dollar equipment, from acquisition to disposal. It integrates maintenance schedules with production plans and uses predictive analytics to prevent downtime.

- Mine-to-Port Supply Chain Logistics: Manages the complex journey of materials, tracking stockpiles, coordinating rail and ship schedules, and managing sales contracts and commodity pricing.

- Financials for Capital-Intensive Projects: Handles complex accounting requirements, including joint venture accounting, multi-currency transactions, project costing, and managing the high capital expenditure typical of mining projects.

- Integration with Mine Planning Software: Connects with specialized software (like those from Hexagon or Dassault Systèmes) to ensure that operational execution aligns with the long-term life-of-mine plan.

The ERP Showdown: A Comparative Look at Leading Solutions for Mining

Choosing an ERP is a monumental decision for a mining company. The leading platforms offer powerful, industry-specific solutions. Here’s how they compare in 2025.

Forging a Digital Future

The mining company of the future will be defined by its ability to harness data. It will be safer, more productive, and a better steward of the environment. This future is not possible without a powerful, integrated digital core.

- For the global mining giants managing a diverse portfolio of assets and complex supply chains, SAP S/4HANA offers the most comprehensive, integrated platform.

- For forward-thinking companies seeking a modern, all-in-one cloud platform to unify their business, Oracle Fusion Cloud ERP provides a compelling, AI-driven alternative.

- For operations where maximizing the performance of every single asset is the number one priority, Infor CloudSuite with its best-in-class EAM is an undeniable leader.

- For asset-intensive companies with complex project and service management needs, particularly in remote locations, IFS Cloud presents a uniquely unified and capable solution.

By selecting the right ERP partner, mining leaders can do more than just improve their bottom line. They can build a resilient, sustainable, and transparent operation that has the trust of its investors, employees, and communities—truly digging deeper to forge a better future.

💌 Enjoyed this article?

If you found this post valuable, subscribe to my newsletter for more insights on digital transformation, AI, and business innovation.

👉 Subscribe to the newsletterOr let’s connect on LinkedIn — I share weekly content that’s practical for CIOs, CFOs, and transformation leaders.

🔗 Connect with me on LinkedIn